As a professional...

Candy tin box packaging production process and production process

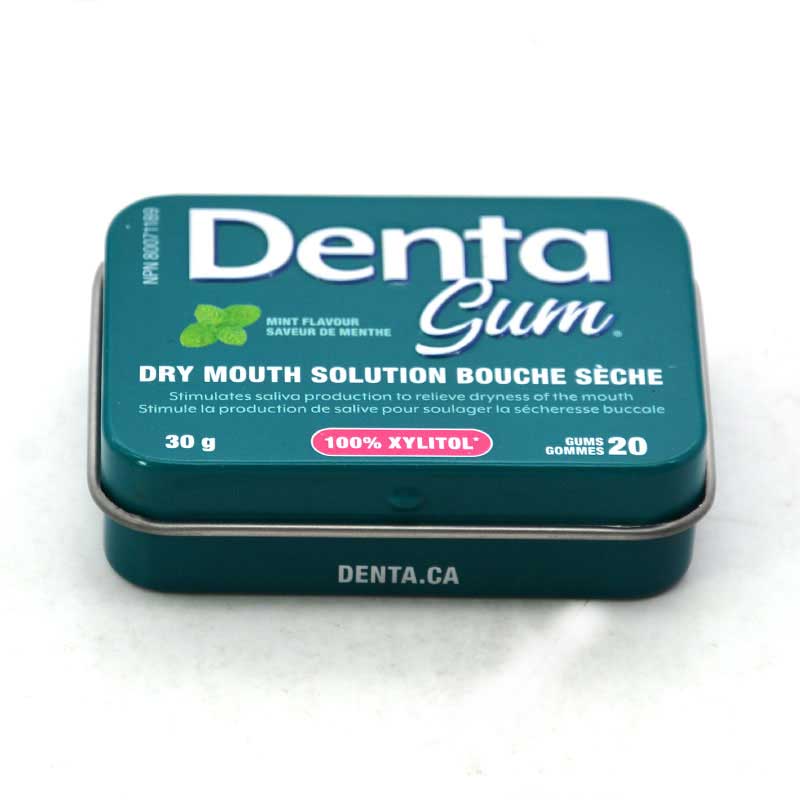

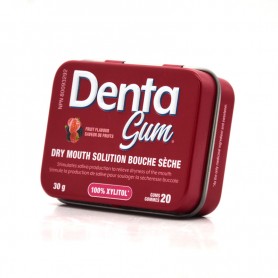

There are a series of processes in the production of candy tin boxes. The colorful candy tin boxes we see are printed in spot colors or four-color printing. However, because of the special nature of the tin box, its printing process is different from other papers. The candy box is not the same. Tin boxes are more and more widely used in packaging in various industries. With the continuous upgrading of industrial technology, the production process of tin boxes is becoming more and more sophisticated. Unlike other packaging, candy tin box packaging has its own unique set. The production system, then how to print the candy tin box, I will explain to you below.

1. Purchase tinplate materials

Purchasing raw materials is the first step in the production of candy tin boxes. After the customer places an order, he must typeset according to the requirements of the order, select the thickness and type of the iron material, and check whether the iron material has scratches and whether the lines are uniform.

2. Printing of tinplate

The raw material of the candy tin box needs to be printed in white before color printing, because white is the base color of all colors, and then printing in color after white printing can better highlight the color. A very important part of the entire production process during printing affects the overall appearance of the product. Affected by the ink coverage, it often requires a monochrome machine to be whitened twice, and the whiteness can reach about 80%. Moreover, it is required that the white paint has a good bonding force with the tinplate can, and can withstand high temperature baking without discoloration. The food tin box factory said that tinplate can printing has relatively high requirements for color. In addition to the high degree of water resistance of the pigment, the coloring power and durability of the pigment are also relatively high. The food tin box factory said that in addition to the general In addition to the characteristics of offset printing ink, it should also have heat resistance. Because the surface of the tinplate can is smooth and will not penetrate water, the ink is heat-fixed and needs to be baked at high temperature.

Iron material printing uses offset printing, which is more difficult than paper printing, and the color difference is not easy to control. At the same time, since the surface of the candy tin box made of tinplate does not penetrate water, it is necessary to equip a drying room in the printing process. The tin box manufacturer stated that the printed ink needs to be baked at a high temperature to fully bond with the surface and is insoluble in water. The non-absorption of solvents is also a big difference between tinplate printing and other offset printing, and it is also a problem that we need to pay special attention to. The candy tin box printing line made of tinplate will be longer than other offset printing. Therefore, the effect of iron printing and the design effect will often have a slight color difference, as long as it is within the acceptable range.

3. Tinplate shearing process

After the iron material is printed and dried in oil, since the whole sheet is printed on the large iron during printing, it needs to be cut according to the cutting position. The cutting needs to be careful, and it must be cut accurately according to the cutting line. If there is a slight deviation, the iron material will be scrapped.

4. Stamping process of candy tin box

Stamping is the core process of making candy tin boxes. According to the different processes of tin boxes, the degree of complexity and simplicity of the process is also different. It is worth noting that stamping is the process with the largest material loss in the entire can-making process. Therefore, the operating rules must be standardized when stamping, and the sample production must be strictly followed to handle with care to avoid scratches on the iron material.

5. Packaging

Packaging is the last process of candy tin box production. After cleaning, the finished candy tin box is packed and stored in accordance with the customer's packaging requirements. In the packaging process, two links are very important. One is cleaning. The oil stains and fingerprints on the surface of the candy tin box should be cleaned when stamping. The second is inspection. During the packaging process, there are defective products that do not meet the requirements and need to be selected. come out.

Good quality candy tin boxes are inseparable from a strict operating system. The manufacturer of candy tin boxes takes "safety, high efficiency, high quality, and low consumption" as the management philosophy, and has formed a unique quality supervision system, with excellent quality Won the trust of our customers, here, for many years, we have won the trust and support of new and old customers.

Summary: The whole production process of candy tin box includes

(1) Confirm the design document

(2) Draw a drawing of the size of the tinplate material

(3) Send the cutting size drawing to the customer for design

(4) Proofreading of customer design drawings

(5) Out of paper manuscript of film

(6) Film proofreading

(7) The customer confirms the design paper draft

(8) Make product samples

(9) Making candy tin box samples

(9) The customer confirms the model of the candy tin box

(10) The customer places an order

(11) Typesetting and printing

(12) Color confirmation is OK

(13) Cut

(14) Stamping (automatic line)

(15) Finished product

(16) Packaging

(17) Shipment

.png)

.jpg)

.jpg)

.jpg)

Latest comments