During the COVID-19 pandemic, carton packaging, metal packaging and the development trend of the paper industry

The future of packaging has never been so multi-faceted, because environmentally conscious consumers continue to inspire creative changes in the traditional industry of packaging. But before we consider what will happen in the future, we should first admit that the new crown epidemic has already produced tremendous changes and lasting effects on our industry.

Multiple global lockdowns have forced changes in consumer behavior and shopping habits, resulting in a 46% increase in e-commerce. The boom in online shopping during the COVID-19 pandemic has brought more packaging deliveries than ever before, all of which urgently need to keep up with market demand. As the packaging is hurriedly thrown from the warehouse to the truck, and then to the door, its strength is more concerned than ever. Because the demand for sturdy cartons is constantly growing, and can safely store your goods under any delivery conditions.

But the new crown epidemic is not the only catalyst. With the decline of the physical retail industry, e-commerce has exploded, and with it, consumers have more awareness of the volume of packaging delivery. Therefore, sustainability and the use of more recycled materials have become equally important. Most cartons today are made of about 50% recycled corrugated materials, half of the metal packaging boxes are made of tin-plated iron, and every ton of packaging material reused can help avoid damage to the environment.

The disadvantage of recycled fiber is that it becomes shorter after each repeated use, which may continuously weaken the characteristics of recycled fiber. Generally, after 5-7 cycles, the fiber can no longer be used. From a practical point of view, this means that the structural integrity of recycled corrugated boxes depends on the quality of raw materials. There are many ways to overcome this problem, but in the end there is a balance between intensity and sustainability, not to mention cost. This is a difficult problem to deal with. Metal packaging boxes can be recycled and reused indefinitely, achieving a balance between strength and sustainability, and recycling costs are lower than cartons.

Since the strength can only be measured after the paper is made, the process optimization opportunities to achieve the correct ratio of raw materials, virgin materials and recycled materials to meet specifications are limited. Therefore, it is not surprising that the demand for intensity virtual measurement released by ABB last year has surged. It creates an online calculation that enables paper and packaging manufacturers to better manage strength characteristics within their target limits, thereby producing more paper that meets specifications at a lower cost, while also reducing the use of raw materials. ABB has also expanded the use of online fiber measurement to better optimize fiber combination.

What other factors are driving this change?

The new crown epidemic will continue to have a long-term impact on the future of e-commerce and packaging. According to McKinsey & Company, global demand for packaging is growing, and sales in 2021 will exceed the $1 trillion mark.

In the past 18 months, we have seen the demand for corrugated boxes surge with each blockade, which has brought light to the paper packaging industry with a core value of US$350 billion in the e-commerce economy. According to data from consulting firm Smithers, the amount of cardboard used to deliver goods from retailers to households has surged by nearly 40% last year, and by the end of 2020, Fischer International confirmed that U.S. cardboard paper consumption has reached 40 years. At the highest level, driven by the growth of corrugated packaging, the operating capacity of the paper industry has grown at a rate not seen in more than 10 years.

Sustainability is one of the biggest contributors to positive changes in our industry, as we see a clear shift in packaging to use less material and more natural packaging. The company now has the responsibility and vested interests to serve the needs of emerging consumers interested in a green future. The unusually high level of e-commerce, coupled with the desire of the younger generation to support companies that conform to their beliefs, has caused people to reassess the waste problem and gradually move away from retailers with excessive or unsustainable packaging.

The evolution of packaging will also be driven to a large extent by demographic changes and consumer trends, such as the increase in urbanization rates and related phenomena, namely the takeaway culture and the demand for convenience. We have seen everything from portable food containers to paper straws. Although its durability is not as good as plastic, restaurants and consumers often choose it. This proves that the desire to reduce waste has changed, and companies need to find ways to optimize the use of packaging materials and maximize cost-effectiveness.

This emotional change is largely encouraged and strengthened by government regulatory changes. The most notable is the European Commission’s directive on single-use plastics (SUP), which came into effect in 2019 and is now expanding into the paper field. This triggered a gradual ban on plastic shopping bags, forcing us to buy reusable or paper substitutes.

Tips for e-commerce companies to cope with the ever-changing packaging industry

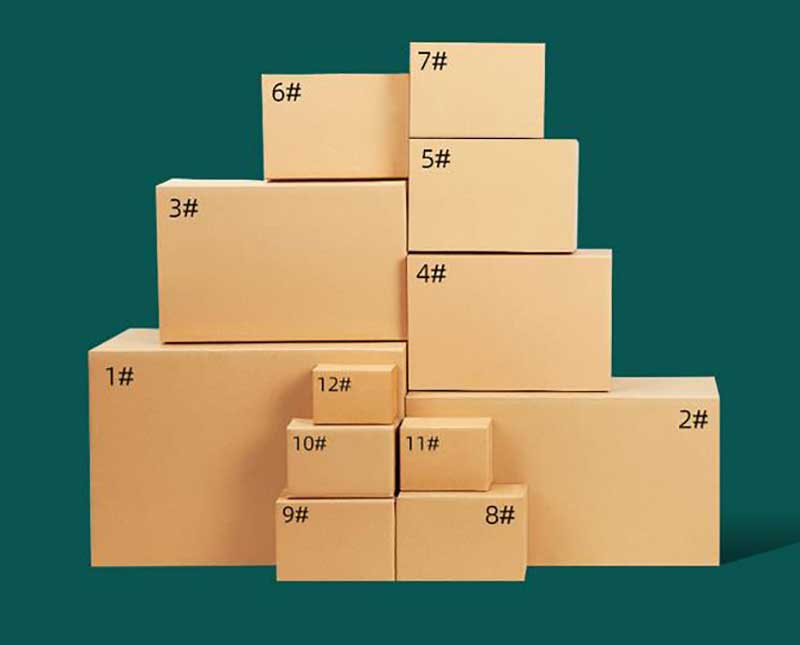

Packaging manufacturers need to strike a balance between sustainability and consumer preferences, while ensuring that packaging can perform its desired role. The packaging strength needs to be consistent with the product type to provide a strong and high-quality product. The key is to know the source of the raw materials used to make the carton or metal packaging box.

The biggest challenge will be to keep the company relevant in a rapidly changing and evolving market. New entrepreneurs, new lifestyles, new places, and new industries have brought cutting-edge changes. The rise of e-commerce highlights trends and topics such as improving product safety, "out of the box" experience, anti-counterfeiting measures, and last-mile delivery optimization.

All in all, packaging manufacturers must innovate to stay competitive and bravely do more than simply improve their packaging methods. We need to prepare for the circular economy and change our way of thinking so that packaging can play an important role in building a positive future.

Latest comments