As a professional...

Finished product inspection procedures and inspection regulations

1. Purpose of inspection

In order to ensure that the products meet customer requirements, the quality of the products before leaving the factory is verified.

2. The scope of inspection

The inspection process of packaged finished products, finished products in stock, and finished products before shipment.

3. Definition of inspection

Outgoing Inspection (FQC/OQC): refers to the inspection performed before the product is shipped to ensure that the shipped product meets the customer's quality requirements, and the product that has passed the inspection can be released for shipment. Shipment inspection is generally carried out random inspection, and the records of the shipment inspection results are sometimes provided to customers according to customer requirements.

4. Duties

(1) QE of Quality Control Department:

A. Collection, establishment and provision of finished product inspection standards, original orders, inspections, etc.;

B. Auditing, reporting and tracking of abnormal quality;

C. Sorting and archiving of quality records, statistical analysis;

D. Customer inspection preparation, escort and recording, sorting and publishing of inspection results, customer requirements, etc., and tracking of processing results.

4.1.2. Product inspection PQC:

A. Inspection and judgment of packaged finished products (including first article inspection) and finished products in stock.

B. Fill in finished product inspection records, collect quality records, and summarize them to QE statistics of quality control department;

C. Feedback, handling, tracking of quality problems and implementation and tracking of corrective and preventive measures;

D. Control and labeling of defective products.

(2). OQC of Quality Control Department:

A. Organize and prepare inspection basis, and conduct inspection in accordance with it.

B. Execution of inspection of finished goods in stock\ finished goods out of shipment, feedback and supervision of exceptions.

C. Fill in and summarize the shipment inspection report.

(3). Material warehouse: finished product packaging, finished product storage, finished product loading.

(4). Manufacturing unit: self-inspection of products, proposal and treatment of corrective and preventive measures for abnormal quality.

(5). Technical Department: Determination and guidance of technical data, packaging methods, and container loading methods.

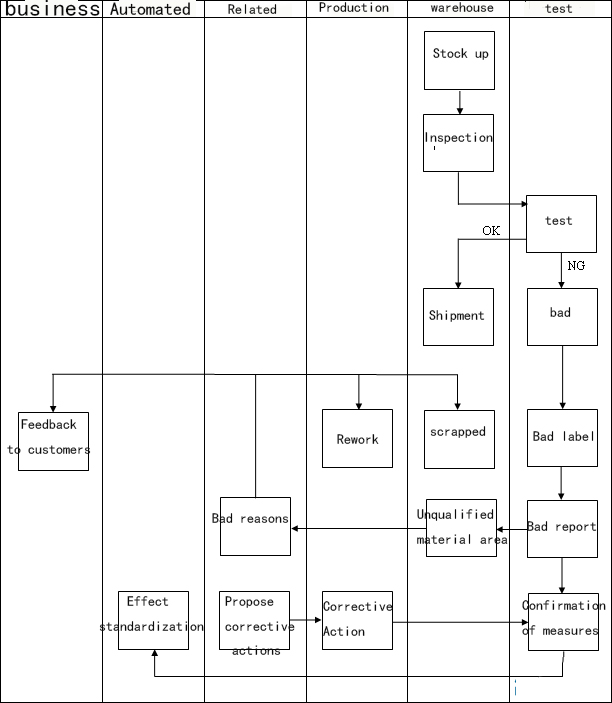

Work flow chart of finished product shipment inspection:

.png)

.jpg)

.jpg)

.jpg)

Latest comments