Personalized metal...

Process flow of biscuit metal box

Recently, we received an order inquiry email from the British Mars food manufacturer (headquartered in Slough, Berkshire) and Associated British Foods PLC, regarding the qualification and production capacity of our factory, the delivery cycle and the factory making biscuit iron The problem with the box process. We have provided more than 300,000 food tins for Mars in the first three quarters of this year, including butter biscuit tins, butter cookie tins, candy tins, chocolate tins, mints tins and pastry tins. The factory completed the production and smooth transportation within the delivery time, and introduced our entire food biscuit tin box production process to Mars in the UK, which received positive comments from them. This article will introduce the process of making tin boxes in the factory.

1. Selected iron materials are required to make food biscuit tin boxes

Shangzhimei generally orders the most suitable tinplate raw materials according to the recent layout drawing after confirming the order. The types of iron materials include: frosted iron, silver iron, galvanized iron, etc. The iron materials are usually stored directly in the factory warehouse. Regarding the quality of iron materials For the identification, you can usually use visual inspection to see if there are scratches on the surface, whether the lines are uniform, whether there are rust spots, etc., and the thickness can be measured with a micrometer.

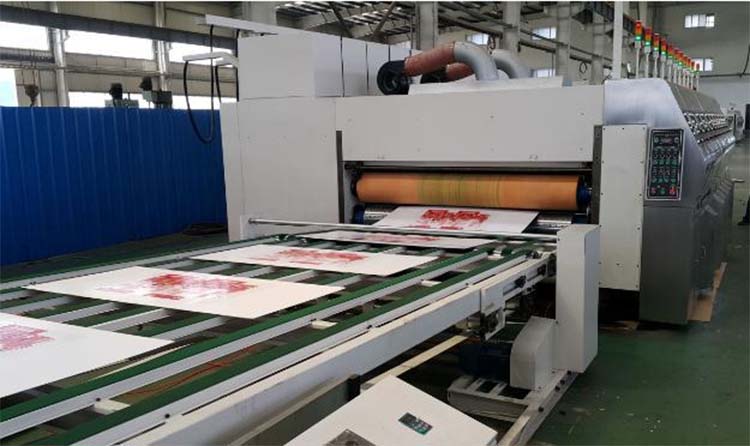

2. Printing of food biscuit tin box

After the food biscuit tin box design drawings are handed over to the film and typesetting printing department, the printing department can perform layout and imposition printing. Normally, samples are provided to the printing department to follow the colors. The thing to pay attention to during the printing process is to read When printing and toning, the color of the same board is the same, whether the registration is accurate, whether there are stains, whether there are scars, etc., these problems are generally controlled by the printing department.

3, the tailoring of the tin box of food biscuits

Many customers think that printing is done after the box is made. In fact, it is not. It needs to be printed first. After the printed iron material is sent to the production department, it can be cut according to the row cutting lathe. It is necessary to pay attention to the cutting process. To see whether the operator cuts according to the knife edge line, whether the length is uniform, etc., whether the workers scratch each other when unwinding, etc., all these require strict quality inspection at the initial operating station.

4, stamping of food biscuit tin box

The iron sheet is pressed into a shape on a punching machine. This is the most important process in making a food biscuit tin box. Usually, an iron box can be completed in many steps. The number of stamping processes depends on the box structure (the more complex the box structure, the more processes). The general process of a two-piece can with an independent lid is: lid: opening-flashing-coiling. Bottom: cutting-flashing-pre-coiling line-coiling line. The process at the bottom of the iron box is: the material is usually lost during the stamping process. Pay attention to whether the work operation is standardized, whether the surface of the product is scratched, whether the coil is sewn, and whether the button is fastened. The usual practice is to arrange the production of large samples for confirmation before the production of large goods, and to produce according to the confirmed large samples, which can reduce a lot of trouble.

5, the packaging of food biscuit tin box

After the food biscuit tin box is stamped, the packaging department will be responsible for cleaning and assembly, plastic bag filling and boxing. This link is the final process of making the food biscuit tin box. The cleaning of the food biscuit tin box is very important. All work must be cleaned before packaging, and then packaged in accordance with the "Food Packaging Guidelines". For food biscuit tin boxes with many styles, the model number and box mark must be aligned and placed. Pay attention to the packaging process The purpose is to prevent defective products from flowing into the finished product, and the packing quantity must be accurate.

The above is the production process of food biscuit tin box. I hope to help friends in need. Only the visually exquisite high-end food biscuit tin box packaging can stand out on the shelf. Our factory has a professional design and development team that can consider packaging from many aspects. Design and the company’s brand culture, we pay attention to visual marketing, we will be able to design a high-end packaging suitable for your products, our craftsmanship and other aspects have been accumulated for many years, and the quality can be well controlled. If you need customized food For biscuit tin box and tin can packaging, we are the right choice, and we will definitely go hand in hand with you.

Latest comments