As a professional...

The difference between the combined printing and the special printing of the packaging box

The difference between combined printing and special printing

Before printing tin box packaging, you may not know that there are actually two ways of printing: split printing and special printing. The following will explain the difference between the two, so that you can choose according to the needs you want to print. suitable printing method.

First of all, let’s briefly talk about the difference between special edition printing and combined edition printing. Special edition printing refers to the printed finished product of the whole set of editions. The same manuscript of the same customer is not merged with others, so the printed content is unique. Sex and quantity.

The printing volume of plywood printing is small and the paper is popular. The printed files provided must meet the characteristics of the printing specifications before they can be submitted to the plywood factory, so that the manufacturer can combine their own manuscripts with other people's manuscripts and print them together.

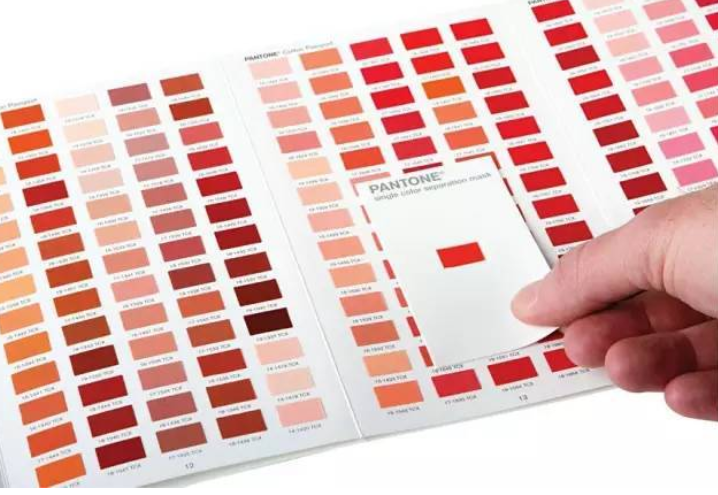

Special edition printing takes the line of quality first. Your own printed matter is printed with its own independent edition, and there is no need to share editions with others. Therefore, special colors, special paper materials, and specifications can be made according to your needs. The former printing factory will provide proofing services to let you see whether the printed colors meet the needs of customers. You can also follow the machine during printing, and the restrictions on design files are also comparable to the freedom of the version.

Because of independent plate making, the printing fee needs to cover the printing fee, but the printing fee is fixed, so when the printing volume is large, the printing fee will be diluted by the quantity, and the more printing, the cheaper. Although the independent version is more expensive, designers or brands with high color requirements insist on using special printing even if the number of prints is small.

In addition, before the special edition is printed, just to adjust the color, adjust the customer satisfaction and make the ink stable, it will cost a lot of paper first, so it is not unreasonable that the special edition printing will be more expensive!

Combined printing takes the economic route. Your files will be put together with the files of other families, so that you can share the cost of the version together, and you can also achieve the purpose of printing a small amount.

Because the combined version needs to maximize the benefits, for different products such as business cards, flyers, posters, greeting cards, stickers, etc., manufacturers will propose the standard specifications and the best printing quantity. Only in this way can there be a way to effectively print The version fills up without wasting any space. If the size you want to make, or the shape manufacturer does not provide the corresponding die, you must make the plate independently!

Because the customer's design draft is made together with the design draft of other customers, the design draft will cause color difference during printing due to the different make-up positions of the upper, lower, left, and right layouts. Therefore, the printing master will use the average tone as the benchmark when grasping the color, so usually the printing color will be different. There is an error of 10% up and down. The same design will also produce color difference due to the different control of the printing machine, ink and printing master during overprinting.

.png)

.jpg)

.jpg)

.jpg)

Latest comments