As a direct tin box...

Packaging box manufacturers wholesale 7 types of packaging

Remember how you felt when you picked up your first iPhone? Remove the plastic seal and feel the stylish white box? By touching the box for the first time, you have already felt the importance, quality and importance of the device. This is no coincidence! Apple has meticulously planned how they package their products to match their brands that provide top product innovation and consumer experience!

Obviously, the packaging of packaging box manufacturers plays an important role in the perceived value of products, and compared with the continuous innovation of portable technology, packaging box manufacturers have indeed not changed much in the packaging industry in the past few years. With all the packaging and box options available on the market today, it is often difficult to choose the most suitable packaging solution for your product. Let the packaging box manufacturer take you through some of the different types of packaging options that can be used to enhance the product and customer experience

1. Cardboard box

Cardboard is a paper material, light in weight, but strong. It can be easily cut and manipulated to create custom shapes and structures. These characteristics make it an ideal choice for packaging box manufacturers for personalized packaging. It is made by converting fibrous materials from wood or recycled waste paper into pulp and then bleaching it. There are various grades of cardboard packaging, and each grade is suitable for different packaging requirements.

SBS (or solid bleached sulfate) cardboard packaging box manufacturers can be used to package cosmetics, medicines, milk and juice, cosmetics, frozen foods, etc. Choosing kraft paper or CUK (coated unbleached kraft paper) cardboard packaging is suitable for those who like the natural and environmentally friendly appearance of recycled paper and can be used for similar packaging applications. It is generally believed that kraft paper has poor resistance to moisture, so it is not suitable for food-related products or frozen food packaging. With the right combination of design options, the cardboard packaging looks high-end without high-end pricing.

2. Corrugated Box

Corrugated boxes just refer to what is commonly referred to: cardboard. Many people may think of corrugated boxes as "cardboard" because it produces large transportation, shoes and storage boxes. Many people do not realize that there are different types of corrugated boxes, depending on the durability and strength of the box. However, it is easy to identify a certain corrugated material. How does the packaging box manufacturer determine the material? Through its corrugated media (also called grooves). It is easy to identify corrugated materials. It consists of 3 layers of paper, outer lining, inner lining and corrugated medium (also called groove). The corrugated medium gives it strength and rigidity.

The main raw material used to make corrugated cardboard is most recycled paper, which is made of large, high-precision machinery called corrugated cardboard. These types of boards can be reused and recycled again and again as a source of pulp fibers. There are different types of corrugated cardboard, single-sided, double-sided (single-wall), double-wall and triple-wall. Packaging box manufacturers are used to manufacture packaging with different characteristics, performance and strength. The board is cut and folded into different sizes and shapes to become corrugated packaging. Other applications of corrugated cardboard packaging include retail packaging, pizza delivery boxes, and small consumer product packaging.

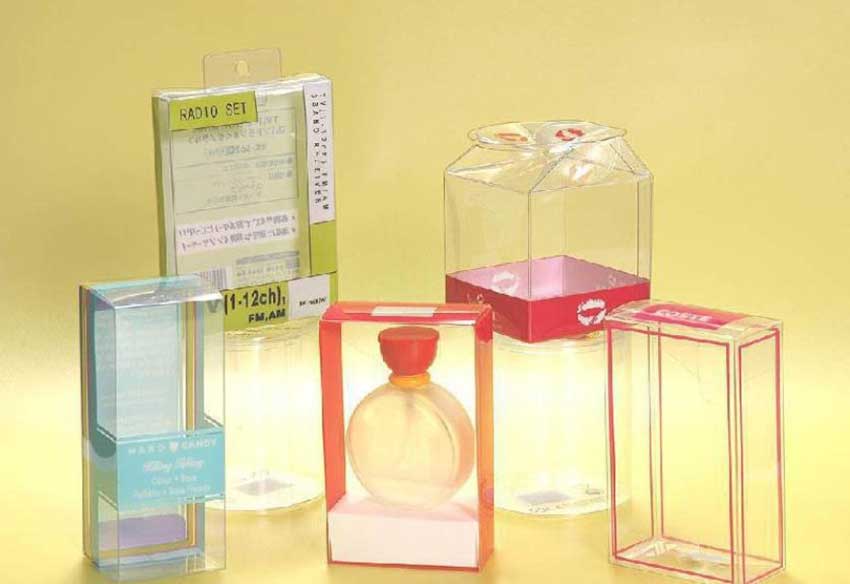

3. Plastic box

Plastics are widely used by packaging box manufacturers in products ranging from spaceships to paper clips. Many traditional materials, such as wood, leather, glass, ceramics, etc., have been replaced by plastics. Plastic box packaging has many advantages that can be recycled, and they are generally more durable than cardboard boxes. Airtight plastic packaging containers help maintain food quality and eliminate any contamination issues. Plastic packaging is not easy to break and can be stored with food under extreme conditions.

Another reason plastic is a popular choice for packaging materials is because it can display products from any angle without opening the package. It is also flexible and lightweight, and can be used with films or coatings to enhance packaging appearance. Contrary to popular belief, plastics are actually recyclable and require less energy to produce new plastics than glass and other materials. Most importantly, it is very cost-effective!

4. Metal tin box

I believe you have always wanted to know the types of boxes they use to pack luxury retail products such as iPhones or Rolex, Tiffany and Mark Jacobs. You have a feeling that it is a cardboard, but it is still uncertain due to its durable and high-quality appearance. This kind of tin-plated tin box material packaging box manufacturer is called rigid box.

The high-quality metal tin box is made of tin-plated iron, and its thickness is 2 times thinner than the cardboard used to construct standard folding cartons. The simplest real-world hard box tin box is the box containing Apple's iPhone and iPad. These boxes are two-piece rigid tin boxes. Compared with cardboard and corrugated boxes, tin boxes are definitely one of the most expensive types of boxes. Tin boxes usually require large mechanical molds and are usually manufactured by hand. Their non-foldable nature also makes them have a higher volume during transportation, which can easily lead to higher shipping costs.

These metal tin box packaging box manufacturers are usually used to promote cosmetics, jewelry, technology and high-end luxury fashion. It is easy to combine features such as platforms, windows, lids, hinges, compartments, domes and embossing in a rigid box.

5. Wooden box

Wooden packaging box manufacturers are used in electronics, medical, food, cosmetics and beverage industries. Wood planks are basically made of recycled materials. It can be easily cut, folded and shaped. It is an affordable packaging option for your products. It has various densities, and the strength depends on the density of the material. If you want to print the image directly on the packaging box, you can use bleach sulfate to treat the wooden packaging box and use CCNB (clay coated back) to make the material more durable.

If your business involves heavy items, you can't use wood packaging, because wood is a light material, suitable for many sundries, such as cereals, crackers, tissue boxes, etc. In addition, if the storage environment of the packaging box manufacturer contains a lot of moisture, the wood is easily weakened, causing discoloration and swelling.

6.Polyethylene box

Polyethylene box, also called pouches or plastic bags, are made of flexible thin plastic film fabric. It is one of the common types of packaging that can carry various products, including food, flowers, waste, chemicals, magazines, etc.

The polyethylene box is durable, light weight, reusable and flexible. Due to the simple structure of the polyethylene box, it can be fully customized in design, style and size, but it is still cost-effective. Depending on the structure, polyethylene boxs can also be recycled for plastics. Most polyethylene boxs have safety features, tape attachments, hanging holes and handles to ensure that the product is safe and reliable, and to attract customers visually.

7. Aluminum metal packaging box

Metal cans are usually found in most coffee and tea packaging. why? It keeps the product dense to maintain the taste, protects it from the entry of bacteria, and helps to extend the shelf life. In addition to food, metal box manufacturers are also used to pack bedding and clothing products. The process involves removing oxygen from the bag to keep the fabric tight and strong to prevent the growth of fungi and other bacteria. Nuts, grains, smoked fish, cheese and cured meats are also packed in foil sealed bags to prevent spoilage.

.jpg)

.jpg)

Latest comments