Details of epe accessories

The production process of EPE pearl cotton: plastic particles-formula mixing-heating extrusion-blowing agent injection-mixing plasticization-extrusion-cooling forming-sizing and cutting-cooling traction- -Flattening-winding-finished product. After this process, first mix polyethylene and other raw materials uniformly with hrxs33, put them into the hopper of the extruder, melt and knead the extruder with a large aspect ratio, and at the same time inject foaming gas and molten monomer into the middle of the extruder at high pressure. Glycerin is uniformly mixed with the melted and kneaded plastic, extruded by the machine head and die, and cooled, drawn, flattened, and wound to form a foamed sheet product.

EPE, also known as EPE, polyethylene foamed cotton, is a new type of environmentally friendly packaging material. It is composed of low-density polyethylene grease through physical foaming to produce countless independent bubbles. It overcomes the shortcomings of ordinary styrofoam that are fragile, deformed and poor in recovery. It has many advantages such as water-proof and moisture-proof, shock-proof, sound insulation, heat preservation, anti-static, good plasticity, strong toughness, recycling, environmental protection, and strong impact resistance. It also has good chemical resistance. It is an ideal substitute for traditional packaging materials.

Origin Guangzhou

Custom processing: Yes

Item No. Mask Holder

Plastic varieties PVC

Whether there is a cover

Delivery type can be customized

Daily production 5000000

Model HS-XH

color: White

Wall thickness 50 (mm) length 250 (mm)

Data sheet

- Personalization

- Shape, Size, Printing, Embossing, Coating...... all can be customized.

- Material

- 0.23mm tinplate

- Shape

- Square tin box

- Usage

- Candy and Mints

- MOQ

- 5000

- Production Lead Time

- 30

- Place of Origin

- Guangdong, China

Our factory was founded in 2005. Covering an area of 10,000 square meters and having more than 300 employees, our company is a professional manufacturer of tinplate packing. Products including:1. Electronic Part Packing: battery tin, bluetooth earphone, cell phone, U disk, CD/DVD.2. Food Packing: cookie, biscuit, candy, chocolate, coffee, health care product.3. Gift Packing: tea, wine, cigarette.4. Other Use: coin, pen/pencil, watch, cosmetic, tin tray, tin bucket, tin badge.We have more than 30 technicians for technical work and mould development and more than 300 sets of equipment which guarantees our high quality products. As a professional manufacturer, we can design any sizes and shapes according to customers' requirements. We have our own professional quality control team to implement our production policy, which ensures our high quality and punctual delivery."High quality, Competitive price and Fantastic service" is our tenet. We sincerely hope to establish long-term business relationship with worldwide customers on the basis of equality and mutual benefit

Best Tin box factory has passed ISO9001: 2008 international quality management system, 7S management certification, Disney, sedex certification, SGS certification, FDA certification.

Real factory

We are real manufacturers Has its own factory building andcomplete production line, all kinds

of equipmen

Each tin can is made of iron material-printing-cutting-stamping-assembly-packaging-step by step.

1) Iron material: Generally, after confirming the order, the most suitable iron material will be ordered according to the recent layout drawing, including the type and size of the iron material. The iron material is usually stored in the warehouse of the factory. The quality of the iron material can be generally inspected visually. The method is to check whether there are scratch marks on the surface, whether the lines are uniform, whether there are rust spots, etc., and the thickness and hardness can be measured with a micrometer.

2) Printing: After the film and typesetting drawings are given to the printing department, the printing department prepares for printing in a row. Usually, the printing department will provide a template for the printing department to follow the color. The thing to pay attention to during the printing process is to see if the printing color can keep up. The template, whether the setting is accurate, whether there are stains, whether there are scars, etc.

3) Cutting: After printing the iron material, you can cut and open the material according to the row of cutting beds. When cutting the mattress, pay attention to whether the operator is cutting according to the knife line and whether the length is consistent and uniform. Whether workers scratch each other when unloading, etc., the quality must be checked at the initial operating station.

4) Stamping: It is to press the iron sheet into shape on the punching machine. This is the most important work of making cans. Usually, a can can be completed in many processes. The general process of the two-piece can of Tiandi Li is: Lid: opening material-flashing-winding. Bottom: Cutting-flashing-pre-coiling line-coiling line.

World lid and bottom process (bottom closure) can process, lid: opening-flashing-coiling can body: opening-pre-bending-angle shear-forming-buckle-punch (buckle) Bottom)-back cover.

If the tin can is hinged, then the lid and the body each have one more process: hinge.

In the stamping process, the product loss is usually the largest. Pay attention to whether the work operation is standardized, whether the product surface is scratched, whether there are batch seams in the coil, and whether the button bone is fastened. The usual practice is to arrange the production of large samples for confirmation before the production of large goods, and to produce according to the confirmed large samples, which can reduce a lot of trouble.

5) Packaging: After the production is completed, the packaging department is responsible for cleaning and assembling, putting in plastic bags and packing. This link is the finishing touch of the product. The cleanliness of the product is very important. Therefore, it is necessary to do a good job of cleaning before packaging, and then package according to the packaging method. For products with many styles, the style number and box mark must be matched. put. In the packaging process, attention should be paid to minimize the influx of defective products into the finished product, and the packing quantity must be accurate.

Packing & Delivery

As we all know, the packing is very important.There are triple protection measurement to guarantee goods.

--all of our tin box logo printing will be packed with plastic film, then there will be no damage

during the shipment to any country. It is the most safe and advanced packing in the world.

---all of our cartons will be marking into red "FRAGILE".

--all of our cartons for bulk order,we suggest packing by pallet, in order to avoid any collision between the

cartons.

shipping ways

DHL,FedEx,UPS,TNT,EMS,China Post, by Air, by Sea or as negotiated.

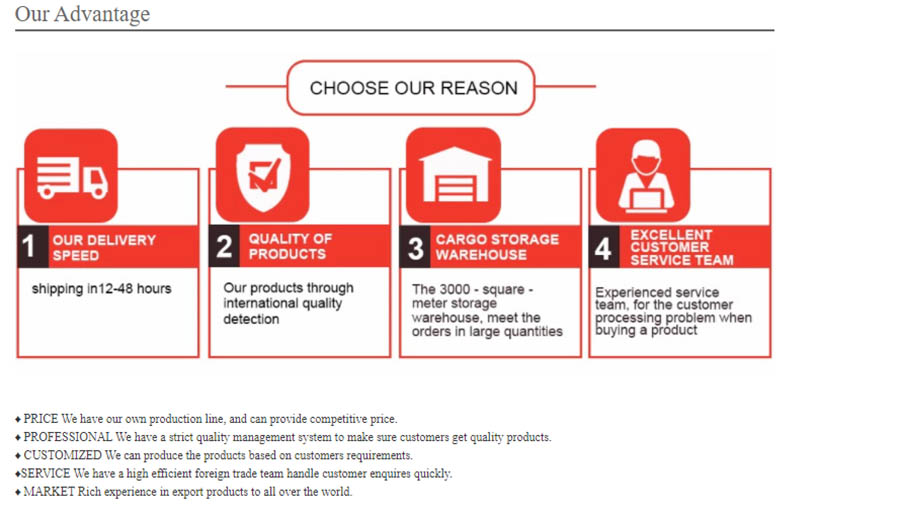

0ur Advantage

CHOOSE OUR REASON

1.OUR DELIVERY SPEED

shipping in12-48 hours

2.QUALITY OFPRODUCTS

Our products through international quality

detection

3.CARGO STORAGE WAREHOUSE

The 3000- square -meter storage warehouse, meet the

orders in large quantities

4.EXCELL .ENT CUSTOMER SERVICE TEAM

Experienced service team, for the customer processing problem when

buying a product

. PRICE We have our own production line, and can provide competitive price.

.PROFESSIONAL We have a stict quality management system to make sure customers get quality products.

.CUSTOMIZED We can produce the products based on customers requirements.

.SERVICE We have a high eficient foreign trade team handle customer enquires quickly.

.MARKET Rich experience in export products to all over the world.

Customization needs

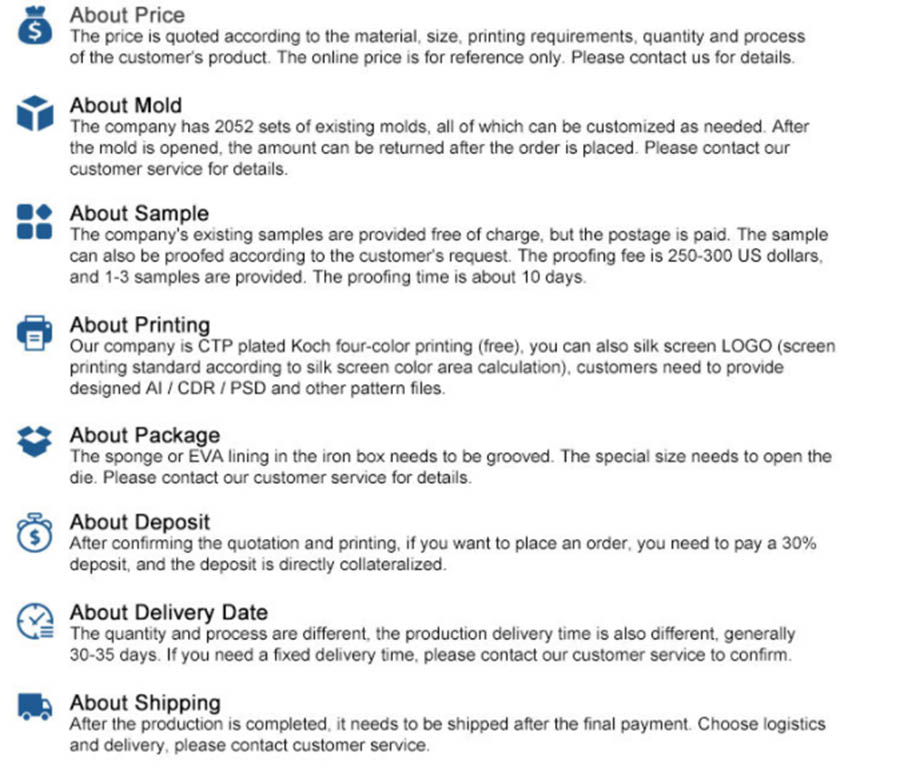

About Price

The price is quoted according to the material, size, printing requirements, quantity and process

of the customer's product. The online price is for reference only. Please contact us for details.

About Mold

The company has 2052 sets of existing molds, all of which can be customized as needed. After

the mold is opened, the amount can be returned after the order is placed. Please contact our

customer service for details.

About Sample

The company's existing samples are provided free of charge, but the postage is paid. The sample

can also be proofed according to the customer's request. The proofing fee is 250-300 US dollars,

and 1-3 samples are provided. The proofing time is about 10 days.

About Printing

Our company is CTP plated Koch four-color printing (ree), you can also silk screen LOGO (screen

printing standard according to silk screen color area calculation), customers need to provide

designed Al/ CDR I PSD and other pattern fles.

About Package

The sponge or EVA lining in the iron box needs to be grooved. The special size needs to open the

die. Please contact our customer service for details.

About Deposit

After confirming the quotation and printing, if you want to place an order, you need to pay a 30%

deposit, and the deposit is directly collateralized.

About Delivery Date

The quantity and process are different, the production delivery time is also different, generally

30-35 days. If you need a fixed delivery time, please contact our customer service to confirm.

About Shipping

After the production is completed, it needs to be shipped after the final payment. Choose logistics

and delivery, please contact customer service.