Commonly used inner support materials for metal tin boxes

I believe everyone should know about the inner support accessories of the box, so how to understand this inner lining? The inner lining means that in addition to the packaging of the whiteboard box, color box, metal box, and outer box, an inner lining needs to be placed inside. This lining can be foam, plastic, or other materials. . In addition, the role of the lining is to protect the product from damage during transportation as much as possible.

In terms of materials, the lining of the box includes EVA lining (EVA can be flocked, but the cost is slightly increased.), pearl cotton lining, sponge lining, paper lining, plastic lining, etc. The following packaging design company will simply tell you some of the performance of the inner tray.

First of all, EVA lining, in terms of performance, has environmental protection and non-environmental protection, as well as anti-static and fireproof. In terms of color, there are white, black, colored, etc. White and black are the most common colors, but the colors are different, and some colors need to be customized. If the customer insists on using this color, he must tell the factory in advance, because this customization takes time.

EPE lining, in terms of performance, there are environmentally friendly EPE lining and anti-static EPE lining. Colors are white, black, red. Sponge lining, in terms of performance, environmental protection sponge lining, anti-static sponge lining and fire-proof sponge lining are available in black, white and color. Of course, the color part must be customized, unless there are ready-made colors

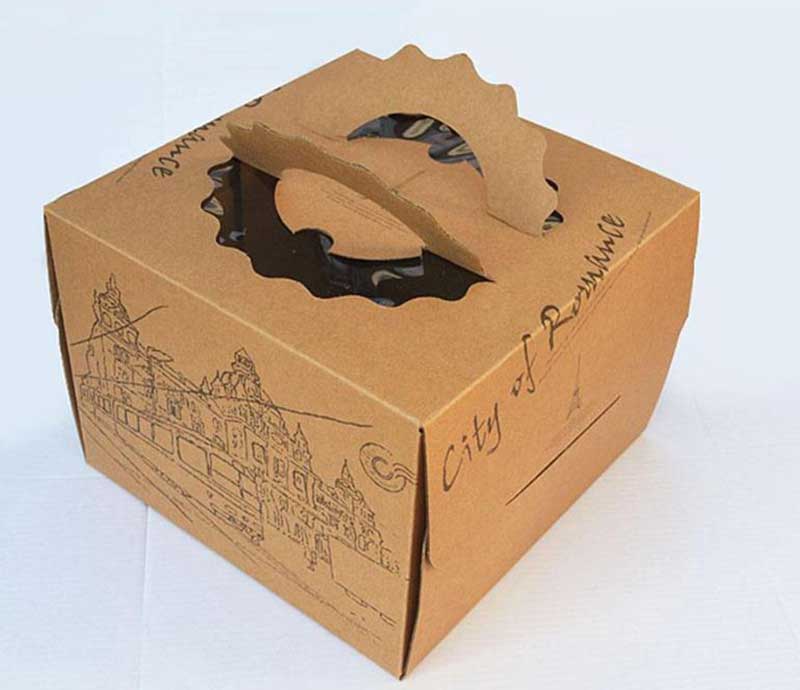

As for the paper lining, the paper is environmentally friendly and recyclable. It is a commonly used lining now. It is easy to load and unload, resists buffering, and can effectively reduce product loss. This kind of inner support material is used more, because the cost is low, and it can also play a protective role, and the surface used is much wider than EVA.

No matter which material is used for the inner lining of the packaging box, it is necessary to consider the positioning of the product and the target audience of the product, and blindly pursuing a good material, which is asymmetrical with the material of the outer box, will not play a good role. This requires the packaging design company to put forward corresponding suggestions for customers to choose according to the attributes of the product.

Latest comments