As a professional...

How is the price of customized tin box generally calculated

The price calculation of customized tin box is a complex process, which is affected by multiple factors such as tinplate raw material price, tin box thickness, specifications and dimensions, processing technology, quantity and labor costs. When customizing tin boxes, customers need to consider the following factors according to their needs and budget and choose a suitable tin box customization plan.

1. Raw material cost

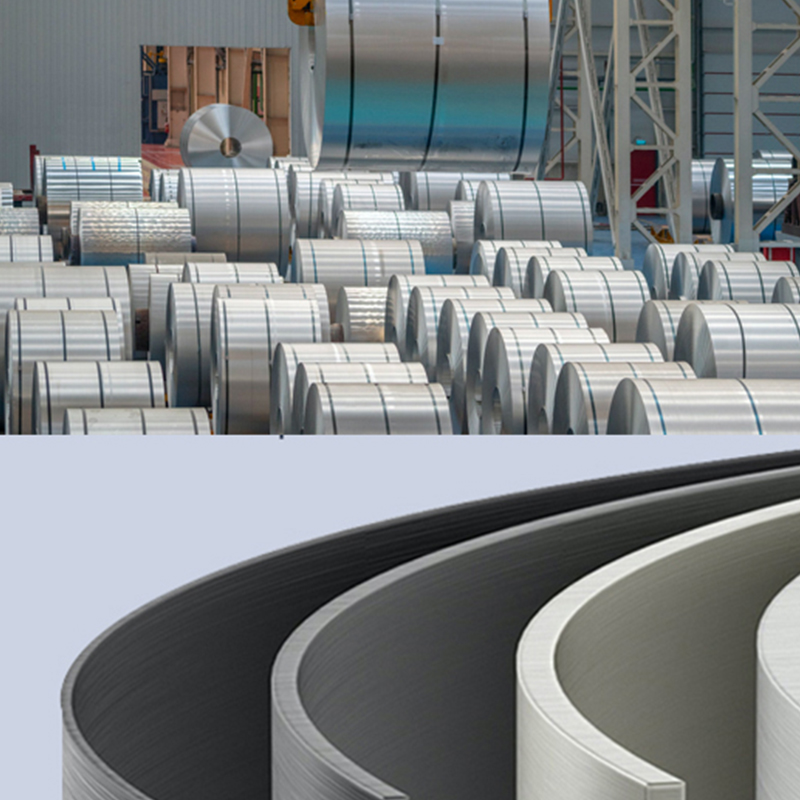

Tin material: Generally, tinplate is commonly used for tin boxes. Its price will fluctuate due to factors such as market supply and demand, which directly affects the cost of tin boxes. For example, the price of tinplate with high tin plating and good quality is relatively high.

Tin box thickness: Different specifications and processing technologies have different requirements for tin material thickness, ranging from 0.23mm to 0.38mm. The larger the tin box and the higher the process requirements, the thicker the tin material required, and the higher the cost. For example, large storage tin boxes use more materials than small jewelry tin boxes, and the cost increases accordingly.

2. Specifications and dimensions

Shape: Different shapes of tin boxes have different material requirements. The round tin box has a simpler production process than the square and special-shaped tin boxes, with high material utilization and low cost; while the square and special-shaped tin boxes are more complicated in cutting and splicing, and there may be more material waste, and the cost will also increase.

Size: The larger the size of the tin box, the more raw materials are required, and the cost will naturally be higher. For example, the cost of a large-sized tea tin box of the same shape is higher than that of a small-sized one, because the large tin box requires more tinplate materials to make.

3. Complexity of processing technology

Forming process: Simple stamping and bending processes have low costs, while complex processes such as stretching and deep drawing have high requirements for equipment and technology, and the cost will also increase. For example, some special-shaped tin boxes with special shapes require multiple complex processes such as multiple stamping, bending and even welding, and the cost will be higher than that of ordinary-shaped tin boxes.

Printing process: The choice of printing process has a greater impact on the price. The cost of ordinary four-color printing is relatively low, while special printing processes such as spot color printing, hot stamping, hot silver, UV printing, embossing, silk screen printing, etc. can improve the texture and beauty of the tin box, but will increase the cost. For example, the printing cost of high-end gift tin boxes using spot color printing and hot stamping technology will be much higher than that of ordinary tin boxes using only four-color printing.

4. Design and mold costs

Design costs: If the customer has unique design requirements, the manufacturer needs to invest in designers to design patterns, structures, etc., and will charge corresponding design fees; if the customer chooses the manufacturer's existing design styles, this cost can be saved.

Mold costs: Customized tin boxes usually require mold making. The mold cost depends on the complexity and size of the tin box. The mold cost of complex shapes and large-sized tin boxes is higher. However, when the cumulative production volume reaches a certain scale, the mold cost may be refunded.

5. Accessories and packaging

Accessories: If the tin box needs to be equipped with accessories such as handbags, steel wire buckles, and rice nails, the cost will increase. Accessories of different materials and qualities have different prices. For example, high-end leather hand straps cost more than ordinary plastic hand buckles.

Packaging: Inner packaging such as plastic packaging, sponge lining, and outer packaging such as paper packaging boxes, etc., all need to be included in the cost. Better lining materials and exquisite outer packaging cartons will increase costs.

6. Quantity

The more you order, the lower the unit cost is usually, because large-scale production can better spread fixed costs and achieve economies of scale. For example, the unit price of customizing 1,000 tin boxes at a time will be much lower than the unit price of customizing 100 tin boxes.

7. Transportation costs

The longer the transportation distance and the more complicated the transportation method, the higher the transportation cost, and the price of customized tin boxes will increase accordingly. If the tin box produced by a foreign tin box manufacturer is transported to the local area, the transportation cost will be higher than that of a local manufacturer, thus affecting the final price of the tin box.

8. Labor cost

The price of customized tin boxes is also affected by labor costs. The production process of an tin box requires multiple processes such as purchasing tin, printing, and cutting. The costs of worker operation, management, and procurement must be considered. The production process of high-end tin boxes is more and the cycle is longer, which will increase labor costs.

.png)

.jpg)

.jpg)

.jpg)

Latest comments