As a professional...

The development trend of the medical packaging metal box industry in the United States

Although the medical packaging metal box may seem simple, it has a major bearing on the quality and safety of medicines. It can protect medicines from environmental influences during storage and use, maintain the original properties of medicines, and also have moisture-proof functions to protect the quality and safety of medicines. Safety. Therefore, the dry humidity, cleanliness parameters, and electronic supervision codes in the production process of medical packaging metal boxes place high requirements on medical packaging metal box manufacturers. In 2021, due to the impact of the pandemic, the market demand for medical products will expand, and the medical packaging metal box industry will also show a steady growth trend.

The concentration of the medical packaging metal box industry will continue to increase

Medical packaging boxes can be divided into outer packaging boxes and inner packaging boxes. Among them, the pharmaceutical packaging box market is relatively fragmented. With the development of the pharmaceutical industry affected by the epidemic and the concentration of medical pharmaceutical companies in the United States, the pharmaceutical packaging box industry will develop rapidly, and the scale of the industry is expected to expand.

Due to the large number of companies in the pharmaceutical industry, the market concentration of medical packaging metal boxes is relatively low. With the advancement of environmental protection measures and the increase in raw material prices, industry concentration is expected to continue to increase. The industry believes that under this background, medical packaging metal box companies with large-scale and specialized production capabilities are expected to benefit. According to statistical data analysis, in 2020, the market share of major pharmaceutical market and pharmaceutical packaging box market enterprises has increased.

The main development trend of the medical packaging metal box industry

At present, under the influence of "COVID-19", the supply chain of the pharmaceutical packaging industry is highly concentrated and demand is high, and the order volume of related enterprises has increased greatly. Some industry insiders pointed out that smart upgrades and centralized integration will become the main development trend of the medical packaging metal box industry in the next few years.

In terms of intelligent upgrades, with the rapid development of the Internet, information technology, and automation technology, the medical packaging machine equipment of the medical packaging metal box is being upgraded in the direction of automation and intelligence. In this context, the pharmaceutical packaging industry urgently needs to follow the direction of intelligent development.

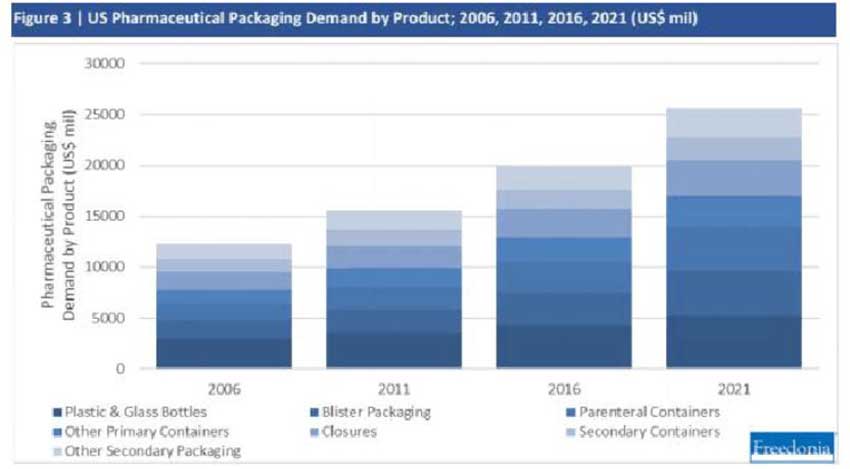

According to data from Pharmaceutical Research and Manufacturers of America, the demand for pharmaceutical packaging products in the United States is expected to reach 26.6 billion yuan in 2021, an annual increase of 1.5%. With the development, production and consumption of ethical and over-the-counter (OTC) drugs, the United States will grow. As new advanced therapies penetrate the market and pharmaceuticals expand their medical indications, packaging will play an increasingly important role in drug delivery and safety, maintenance of drug quality and integrity, and drug resistance compliance. Pharmaceutical packaging companies take industry supply chain management as the entry point, and establish a supply chain management platform to integrate industry supply chains by acquiring a company that serves a supply chain platform covering information flow, logistics, and capital flow in the printing and packaging industry.

In terms of centralized integration, industry experts pointed out that the increase in industry concentration will be the only way for the development of the US pharmaceutical packaging market, and the industry will move towards standards and norms. It is foreseeable that as pharmaceutical companies have higher and higher requirements for the safety and reliability of packaging materials, some small-scale, backward technology, and management problems with medical packaging metal box manufacturers will be eliminated and integrated, and the industry concentration will be With further improvement and the continuous optimization of the production capacity structure, the enterprises in the industry will further move towards scale and specialization, and at the same time continue to grow bigger and stronger, and continue to develop in the direction of internationalization.

Medicine packaging box raw materials

In the past five years, the relative raw material costs of the pharmaceutical packaging products industry in the United States have not changed significantly. Although customers' preference for high value-added metal boxes and related accessories continues to increase, this trend has continued. Continuously improve the quality, performance and processing performance of raw materials, so that manufacturers of pharmaceutical packaging metal boxes can maintain a consistent level of production efficiency while meeting the needs of the upgraded product market. In fact, with the advancement of materials and processing technology, the industry's relative raw material costs are expected to gradually decline in the long term.

So far, plastic resin and metal boxes are the largest amount of raw materials consumed in the production of pharmaceutical packaging products in the United States, that is, about 4.3 billion pounds in 2019. According to the wide range and diversification of services, this trend will continue for a long time. Other pharmaceutical packaging materials have narrow uses. For example, most of the demand for paper and cardboard is in secondary containers, labels and packaging inserts. Gastrointestinal bottles, pre-filled syringes, liquid medicine bottles and topical medicine tanks are mainly used for glass. Pharmaceutical packaging products that are at least partially composed of aluminum foil include blister packs, foldable composite tubes, and unit-dose bags.

The growth opportunities of plastic resin in pharmaceutical packaging products will extend to most types of main containers and closures, as well as closures and several other types of accessories. Based on cost advantages, commercial resins will remain the main plastic materials used in these applications. Paper and metal box plates are establishing niche applications in unit-dose systems, such as blister cards, tape packaging, liquid medication cups, and low-barrier bags. The continued influx of new injection and infusion therapies into the market will increase the demand for glass parenteral packaging products. Efforts to expand the application of metal boxes for pharmaceutical packaging have led to more intense competition between the commercialization of new varieties and plastic films.

It is estimated that the total demand for medical packaging metal box products in the United States is 25.6 billion U.S. dollars. In 2021, it will increase by 5.1% annually from 19.9 billion U.S. dollars in 2016. The growth will reflect the growing production and consumption of ethical and over-the-counter drugs.

.png)

.jpg)

.jpg)

.jpg)

Latest comments