As a professional...

Biscuit packaging box design and packaging manufacturing process

Brief introduction of biscuit packaging box

Biscuits are becoming more and more popular nowadays. Biscuits are divided into many types, such as: crisp biscuits, tough biscuits, fermented biscuits, compressed biscuits, sandwich biscuits, wafer biscuits, cookies, etc., so when designing biscuits , Not only must pay attention to the taste of biscuits, but also design different packaging according to different types.

Biscuit packaging is a comprehensive reflection of brand concept, product characteristics, and consumer psychology, and it directly affects consumers' desire to buy. We are convinced that packaging is a powerful means to establish the harmony between products and consumers. In today's economic globalization, packaging and commodities have been integrated. As a means of realizing commodity value and use value, packaging plays an extremely important role in the fields of production, circulation, sales and consumption. It is an important subject that the business community and design have to pay attention to. The function of packaging is to protect goods, facilitate transportation and storage, and promote sales. As a comprehensive subject, packaging has the dual nature of combining commodities and art.

Protective function design of biscuit packaging box

1.Moisture-proof and mildew-proof, barrier, film smoothness, ink standard regulations

Biscuits are puffed small foods, and their packaging uses composite film bags. According to the technical requirements of food packaging, it should be treated in accordance with the national standards for moisture-proof (GB5048), mildew-proof (GB4768), barrier properties (GB1974-2005), film smoothness (GB10006), and ink properties (GB7707) packaging regulations.

Moisture-proof treatment is generally achieved by PET/VMAL/CPP composite film bags and placing an appropriate amount of desiccant in the package to meet the protection requirements.

The anti-mold performance should be tested according to the anti-mold packaging test method: after testing in accordance with the provisions of (CB4768), the appearance quality and related performance of the food should meet the requirements of the product standard, and no mold will grow during the validity period.

2. The shock resistance of the biscuit box

Biscuit is a fragile product. In the process of product circulation, tinplate boxes are generally used. Tinplate boxes have good cushioning performance and compression resistance. The material and structure of tinplate boxes can also be improved according to different needs, and the cost is low. Therefore, tinplate boxes play a major role in the transportation and packaging of biscuits. After market research, the puffed biscuits are used in tinplate packaging.

3. The light-proof property of the biscuit box

Generally speaking, packaging boxes with transparent films are not recommended.

Protective performance test of biscuit packaging box

In order to check the degree of protection of the packaging box, the packages are tested for stacking, vibration, pressure resistance, and drop. The stacking test is to evaluate the compressive strength of the puffed food packaging box when it is stacked and the protection function of the packaging box for the puffed small food. The vibration test is replaced by a simulated automobile transportation vibration test, which is shaken for 7 seconds on a simulated automobile vibration table to test the protection ability of the packaging on the product.

Common types of biscuit packaging boxes

There are four common types of biscuit packaging, plastic film sealed packaging, wax paper packaging, carton packaging and tinplate packaging.

1. Plastic film sealed packaging of biscuits

The plastic film sealed packaging of biscuits is mainly embodied by the use of plastic materials. Due to the irreplaceable advantages of the plastic packaging box material itself in terms of performance, price and freight, more and more traditional packaging box materials are replaced by plastic packaging. Plastic film is a good moisture-proof packaging material. It is the most widely used in biscuit packaging. There are two main forms: one is in bulk, which means that the measured biscuits are poured into the bag together.

In the middle, then use heat sealing to seal; the other is to wrap, that is, a certain amount of biscuits, generally about 50-100g, arranged neatly, and then wrap and seal with a film.

Features of plastic biscuit packaging box

①The plastic is sealed and has good barrier properties, and the plastic is light in weight, easy to form, simple in packaging, and convenient to sell. This is the advantage of the plastic biscuit packaging box design.

②Disadvantages of the design of the plastic biscuit packaging box: the permeability coefficient to oxygen and carbon monoxide is large, which will cause a chemical reaction between the packaged object and the packaged object. Others, the packaged object will also deteriorate due to oxidation, and the taste will be deteriorated. The aging of plastic products also affects the appearance quality, is not beautiful and practical, and pollutes the environment. The biggest disadvantage is that it pollutes the environment and is not easy to recycle.

2. Wax paper packaging box for biscuits

The simple form of wax paper biscuit packaging box, as long as the biscuit is arranged neatly after being measured, and wrapped and sealed with wax paper. This method shading, moisture-proof and low cost.

3. Paper biscuit packaging box

The carton biscuit packaging box is the main form of biscuit packaging, with square, rectangular, round, irregular and other forms. Whiteboard paper, offset paper, etc. are mostly used as packaging materials. When packing in a carton, the biscuits should be wrapped in film first, and the outside of the box should be wrapped in wax paper or film. Paper products are easy to decay. They can not only recycle recycled paper or be used as plant fertilizer printing materials, but also reduce air pollution and purify the environment. The biscuits are packaged with paper materials, which have good packaging strength, a certain degree of pressure resistance, beautiful appearance, strong commercial properties, good moisture resistance and shading properties, and good printing adaptability and adhesion properties.

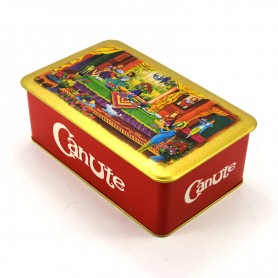

4. Tinplate biscuit box

Tinplate packaging is a biscuit packaging made of color-printed tinplate. There are many types of boxes, such as square, rectangle, cylinder, ellipse and special shape. When packaging, the tin can be processed into various trough-shaped film trays with plastic, which are light, beautiful, and the biscuits are neatly arranged and not easily broken. This kind of packaging has the best airtightness, high packaging strength, bright appearance, generous appearance, excellent shading, and durability, but it requires a lot of space to store empty cans. Therefore, cans and boxes are currently only used in dry bulk packaging or expensive varieties and various gift packaging boxes.

.png)

.jpg)

.jpg)

.jpg)

Latest comments