As a professional...

YU-Gi-Oh! 2020 tin box be customized

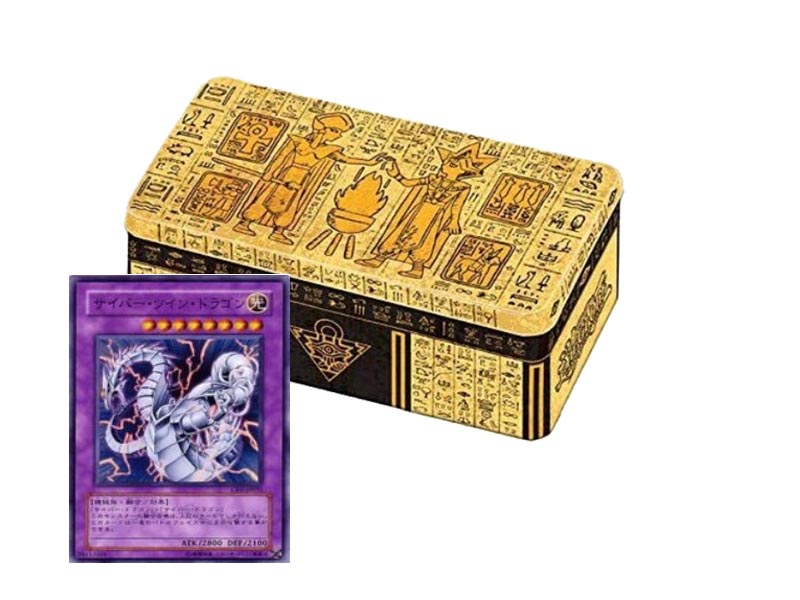

Yu-Gi-Oh! Tin-"Pharaoh and Priest" released on August 27, the latest Yu-Gi-Oh! Tin-"Ancient Duel". The tin can depicts the battle between the pharaoh and the priest in an awesome tin can design. Each jar has 3 Mega Tin 2020 enhanced packaging, which contains some rare and precious edition reprints that have never been printed before. These jars are a great way to get cards that were not available before. The jar will also contain 3 new world premiere cards and the long-awaited Red-Eyes Dragoon. Every Yu-Gi-Oh! Tin box 2020 is specially customized. How is the awesome tin can design made?

The raw material of Yu-Gi-Oh! Cards 2020 Tin box is tin-plated iron, which has good airtightness and pressure resistance, and can better protect precious cards; the first step in making the iron box is how to combine "Pharaoh and The "Priest" pattern is printed on the tinplate. Yu-Gi-Oh! Tin box printing uses the physical properties of water and ink repelling. It uses the pressure exerted by the roller to transfer the graphics on the printing plate to the tin-plated iron through the blanket. This is the offset printing. principle. The tin-plated iron has special physical and chemical properties and printing adsorption capacity, while the printing process and offset printing are different. After finishing all the color registration, the tinned iron needs to be coated with a layer of bright oil on the surface, the purpose is to improve the surface gloss, but also to increase the hardness of the iron material, so that the printing ink layer has a certain degree of flexibility and corrosion resistance , So it can produce an awesome printing effect.

Then the printed tinplate is stamped. Stamping is a kind of metal processing technology, which is widely used in the processing of plastics and metals. It is the process of forming iron materials in an instant by applying pressure. Process the tin-plated iron into the required shape and semi-finished products. And stamping is also divided into cold stamping and hot stamping: cold stamping is metal processing at room temperature, generally suitable for iron materials with a thickness of less than 4mm, and has the advantages of high productivity, high precision and strong stability. The iron box production process under general conditions is: iron material-cutting-stamping-assembly-packaging. The stamping process is an important step in the forming of the iron box. The general process of iron box stamping can be divided into: cutting-pre-bending-cutting angle-forming-buckle-stamping-back cover. After the above process, an awesome Yu-Gi-Oh! Tin box was born.

The above is a brief introduction to how Yu-Gi-Oh! Cards: 2020 Tin box is made. If you don’t really understand the production process, you can contact us or leave a message in the comment area. We will reply to you by email.

Latest comments