As a professional...

Brief introduction of manufacturing process of five-piece tea pot

Tea is a dry product, which is easy to absorb moisture and produce qualitative changes. It has strong absorption of moisture and odor, and the aroma is very volatile. When the tea is not stored properly, under the influence of moisture, temperature and humidity, light, oxygen and other factors, it will cause undesirable biochemical reactions and microbial activities, which will affect the quality of the tea. Therefore, there is a certain amount of container and method used. Requirements. Therefore, tea cans came into being. Tea cans are packed according to customer needs to promote the sale of tea commodities. A good tea pot design can increase the value of tea several times and enhance the brand effect of the product.

Because there is not much knowledge about the manufacturing process and professionalism of tin cans, many tea brands have many questions and concerns when choosing a partner. In order to solve this problem, the following will introduce the manufacturing process and process of tea tin cans (Take a piece of tea tin can as an example), I hope to help you. As shown below

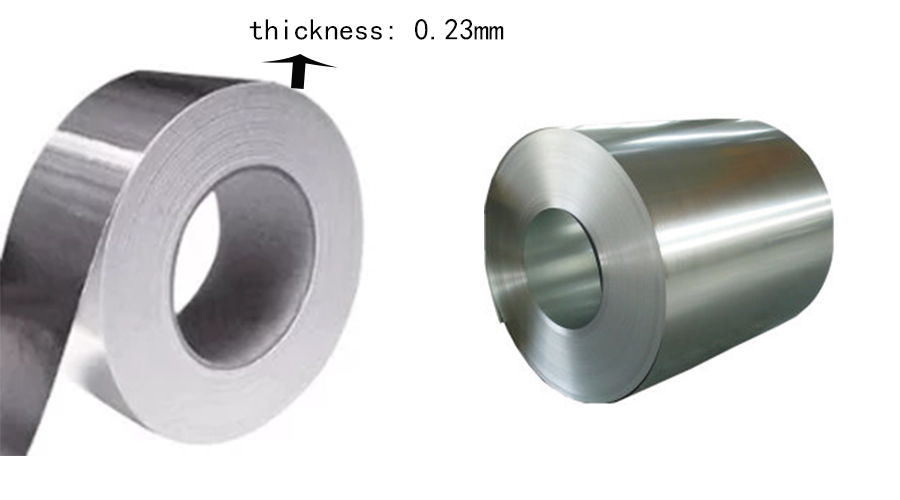

1. Selection of iron can material

A. Tin tea is used for this tea can. It is plated with tin on both sides to prevent corrosion and rust. It has the characteristics of corrosion resistance, non-toxicity, high strength and good ductility. Tin iron is distinguished by different amounts of tin plating, usually between 1.0 and 5.6, expressed as 10#, 25#, 50#, etc.

The commonly used tin content is 2.8 (front and back). The higher the amount of tin plating, the higher the brightness of the iron sheet, the stronger the adhesion, and the poorer the ability to attach to plain iron, easy to scratch. Conversely, the lower the amount of tin plating, the easier it is to burn oil and blacken the deep-drawn iron.

According to the hardness of iron, the commonly used irons are T2.5 and T3. The drawn iron box is suitable for T2.0, and the special requirements for deep drawing are T1 iron, such as tea cans.

B. Thickness of raw materials. The thickness of the iron sheet generally used is in the range of 0.23--0.35.

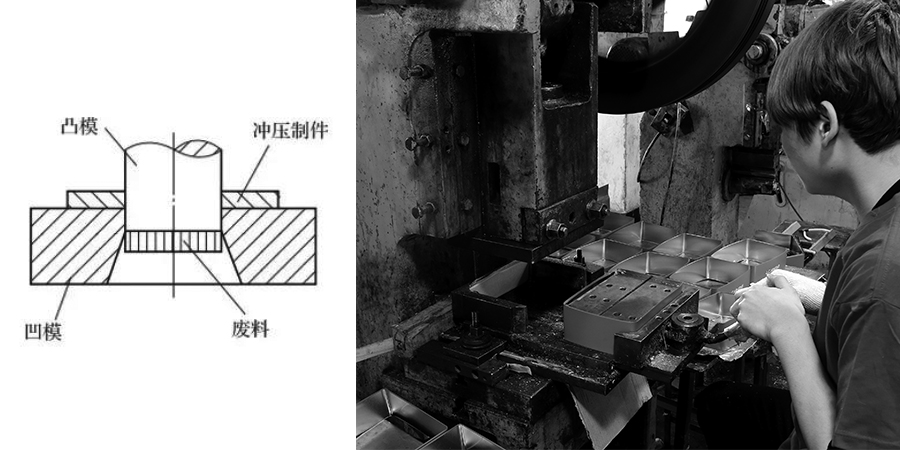

2. The tea tin can is cylindrical in structure, and the molds used in its production are: 3 sets of outer cover (cutting, flashing, coiling), 4 sets of inner cover (cutting, coiling, punching, Press nails), 6 sets of shoulders (cutting, flashing, stretching, punching, winding, and 1 set), 2 sets at the bottom (cutting, flashing) and 1 set of cutting.

3. Explain the basic process of tea tin can processing technology. The stamping equipment and die are used to separate or deform the tin plate material, so as to obtain a blank or part with a certain shape, size and performance. The die is used to separate the blank from the blank with a closed profile. Use blanking to obtain certain shaped parts or blanks. The material in the stamping blank is separated with a closed contour to obtain a part.

4. Printing process of tea pot

This tea tin can adopts the white magnetic printing process (white magnetic ink printing, referred to as white magnetic), a kind of anti-counterfeiting printing technology of special ink, which is filled with magnetic substances for printing.

White magnets are generally divided into three types according to hue:

① Pure white magnetism: yellow phase, yellowish surface. Special adjustment is required. If there is no special requirement, selection is not recommended.

② Blue-white magnetic: blue phase, the surface is bluish. Most white magnets refer to blue and white magnets.

③Red and white magnetism: red phase, reddish surface.

5. Tea tin can quality inspection process

Work flow of quality inspection: accept products to be inspected; extract products to be inspected according to standard sampling standards; inspect products according to inspection standards (or inspection manuals or drawings, or specifications); issue inspection reports.

6. Packing products into storage

In order to ensure that the product is not damaged before being delivered to the customer, the illegal operation of the product in the process of packaging, warehousing, handling, storage, protection, delivery, etc. is eliminated. To ensure the safety of property and personnel in the warehouse, this management procedure is specially formulated.

.png)

.jpg)

.jpg)

.jpg)

Latest comments