As a professional...

Christmas gift tin box production process

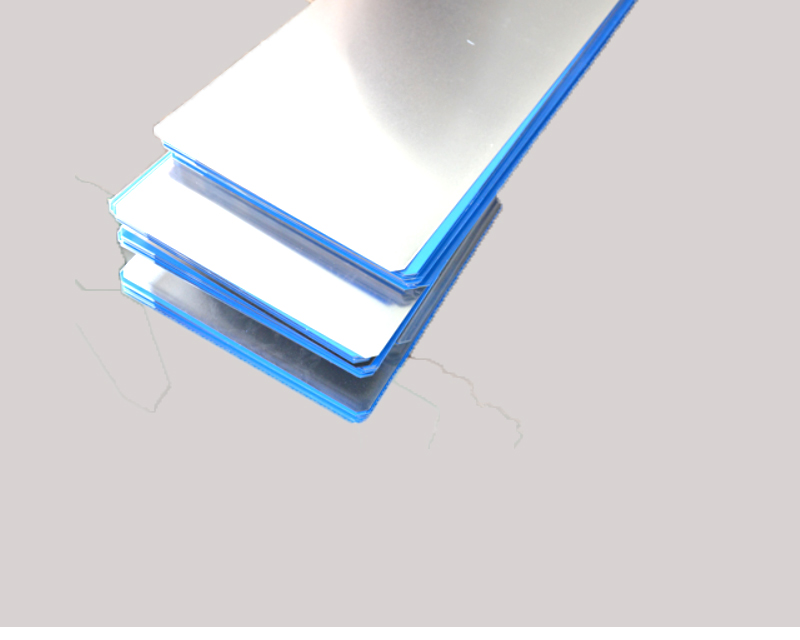

Christmas gift tin boxes are green and environmentally friendly packaging products. Naturally, most of their production methods are physical methods. However, there will be subtle differences in the production process of tin boxes, but all the general process steps are as follows:

1. Cutting: Use a shearing machine to cut the tinplate into a can body plate or a stalk cover and a rough bottom according to the size required by the drawing.

2. Trimming and corner cutting: cut off the upper and lower corners at one end of the rectangular bad material, and cut out a gap on the upper and lower pages at the other end, so that the upper and lower ends of the can body can have two layers of plates. The weight of the material to facilitate flanging and sealing. The chamfer can be cut into a right angle, pagoda shape, or obtuse angle; the cut can be cut into a V shape or a U shape.

3. Crimping: Crimping requires the cooperation of a crimping machine to roll the mouth of the bad material of the can body into a small arc. A pre-bending process)

4. End folding: also called hooking. The end folding in the production of tinplate boxes is to make the can body round each other. Use an end folding machine to fold the two ends to the back and front respectively.

5. Forming: It is carried out on a three-roll machine, so that the upper data and the lower one a rotate in the opposite direction. The iron sheet is rolled into a cylindrical shape under the action of pressure and friction in the middle.

6. Flattening: After the end folds on both sides of the tank are hooked to each other, they are flattened by a flattening machine to form a firm

7. Flanging: The bottom is turned 90 degrees outward or inward. The methods of flanging include spinning flanging and bending flanging. The purpose is to seal the can and ensure the quality of the roll seal.

8. Can sealing: It is carried out on the can sealing machine, so that the can body and the bottom of the can can be sealed through a heavy curling, and the process is square bottom, beat bottom, and deducted.

9. Pressing ribs: The reinforcement ribs are pressed on the can body, which mainly plays the role of decorating the tin box, and at the same time facilitates better opening of the lid.

Verwandte Erzeugnisse

-

HOCHWERTIGE GEBOGENE SÜSSIGKEITSKASTEN

Preis:0,60 $Großhandel billig geprägte Metallverpackungsboxen für Süßigkeiten Blechdosen... -

Schokoladen-Valentinstag-Verpackungs-Blechdose

Preis:0,62 $Größe: 235 * 155 * H57MM Diese Schachtel ist eine rechteckige...

Bitte hinterlassen Sie einenkommentar.

Ähnliche Artikel

-

2020 most creative Christmas gift packaging tin box

Veröffentlicht in: Blechdose als Weihnachtsgeschenk08/05/20203868 Ansicht1 0 GeliebtThere are still more than four months to go before Christmas in 2020. In this holiday, the boundaries of faith and...Read more

2020 most creative Christmas gift packaging tin box

Veröffentlicht in: Blechdose als Weihnachtsgeschenk08/05/20203868 Ansicht1 0 GeliebtThere are still more than four months to go before Christmas in 2020. In this holiday, the boundaries of faith and...Read more -

What is the 2020 Christmas gift? See the list we gave you

08/06/20204101 Ansicht1 6 GeliebtChristmas is coming again! The shopping malls on Main Street will be equipped with cute decorations to make people...Read more

What is the 2020 Christmas gift? See the list we gave you

08/06/20204101 Ansicht1 6 GeliebtChristmas is coming again! The shopping malls on Main Street will be equipped with cute decorations to make people...Read more -

Christmas gift wrapping tin box

08/07/20203836 Ansicht1 15 GeliebtProduct name: Shenzhen Christmas tin box, Christmas tin can, Christmas gift packaging tin box Product introduction:...Read more

Christmas gift wrapping tin box

08/07/20203836 Ansicht1 15 GeliebtProduct name: Shenzhen Christmas tin box, Christmas tin can, Christmas gift packaging tin box Product introduction:...Read more -

Christmas gift tin box quality inspection process

08/10/20204351 Ansicht1 15 GeliebtProcess inspection is to prevent non-conforming products from flowing into the next process, and to inspect the...Read more

Christmas gift tin box quality inspection process

08/10/20204351 Ansicht1 15 GeliebtProcess inspection is to prevent non-conforming products from flowing into the next process, and to inspect the...Read more -

Printing process of Christmas chocolate tin can

08/11/20204020 Ansicht1 54 GeliebtThe printing process of Christmas chocolate tin cans is divided into several processes: color separation, proofing,...Read more

Printing process of Christmas chocolate tin can

08/11/20204020 Ansicht1 54 GeliebtThe printing process of Christmas chocolate tin cans is divided into several processes: color separation, proofing,...Read more

.png)

.jpg)

.jpg)

.jpg)

Latest comments