As a professional...

Customized tinplate tea pot process-Shangzhimei Packaging

In daily life, we will find that packaging has gradually developed towards brand packaging in recent years. Now the packaging can be said that different products have different packaging. Generally speaking, the design of an exquisite gift packaging iron box directly affects the sales volume of the product. How to customize a unique packaging? The following describes the production process of tea packaging tin box by Shang Zhimei.

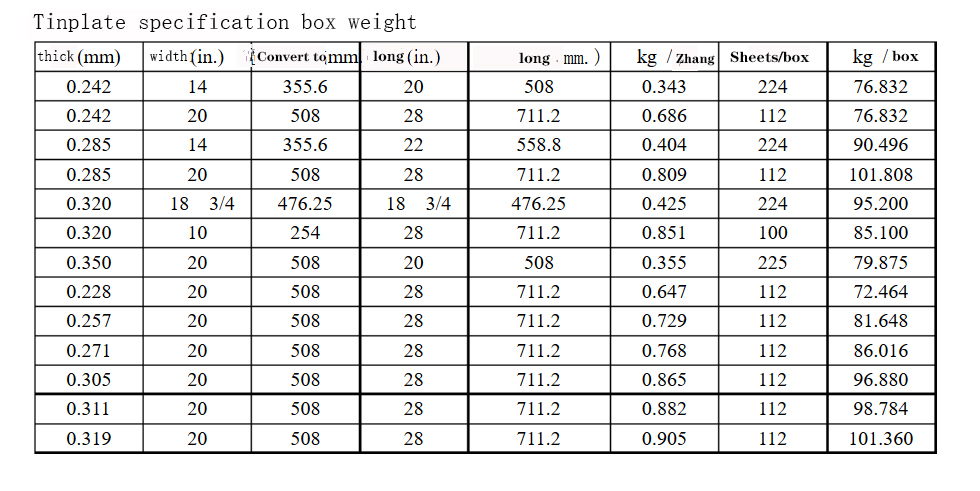

1. Iron sheet selection, including materials (plane iron box, frosted iron), determine the size of the customized moon cake box iron sheet; attached tinplate size specification chart (below)

2. The choice of the inner support material (paper, sponge, PVC, EVA, plastic, etc.), the price of the inner support material varies greatly, and it can be customized according to the customer's quality requirements.

3. Make moon cake tin box mold, divided into three parts: lid mold, box body mold, bottom mold, if the customer needs to customize the special shape of the box shape, you need to open the mold, our company generally costs about 2500-15000 to open a set of molds. The price is determined by the complexity of the box. The simple box price is relatively convenient, otherwise the price is high. Our company has 10 years of experience in making iron boxes and more than 20,000 sets of molds, which can meet the needs of most customers for box type. The manufacturing cost without opening the mold is relatively low. Then, after confirming the process and practice, prepare materials in batches.

4. Tinplate printing.

a. Metal printing is printing on a metal plate, so it is also called metal printing. It is generally printed on the surface of tinned iron or aluminum plate. Metal printing products are mainly used in the manufacture of food packaging boxes, stationery boxes, children's toys and interior decoration products. Metal printing uses hard metal substrates, which are very easy to wear plates, so lithographic printing is used, and graphics are transferred through rubber cylinders. Therefore, the structure of the printing machine is basically the same as that of ordinary printing paper. The metal plate cannot be bent like a paper and attached to the impression cylinder, and can only pass horizontally between the rubber cylinder and the impression cylinder. In addition, the offset printing machine must be equipped with a drying system. The process of sheet metal printing is: sheet metal treatment → printing → drying 1. Sheet metal treatment. Before printing, use a dilute alkaline solution or alcohol to wipe off the dust and oil on the surface of the metal plate.

b. The surface of the metal plate is smooth and non-absorbent. Therefore, the ink printed on the metal sheet must have good adhesion, but also have good heat resistance, light resistance, solvent resistance, resistance to cooking and mechanical impact resistance.

On the metal plate, it is usually printed multiple times, the first time the bottom varnish is printed to protect the metal from corrosion. The second time, the bottom layer was printed with white ink to cover the color of the metal, and then the graphics were printed in order according to the printing color sequence. Last printed gloss

5. The MOQ of the moon cake tin box is printed. The MOQ of the box size above 170*200*300mm is 3000 pieces, and the MOQ of the box size below 110*160*200mm is 5000 pieces.

6. Tinplate stamping

Our automatic punching production line has high production speed and high yield, which improves production efficiency, reduces the workload of workers, and reduces production costs. Automatic sheet metal stamping, including box body stamping, box lid stamping, and box bottom stamping. The stamping steps are all carried out in the stamping die mechanism. Generally, the stamping die chassis mechanism is installed inside the machine table, and the embedded installation is adopted. The left side of the stamping mechanism is provided with a conveyor belt, and the inner two ends of the conveyor belt are provided with drive rollers to convey the stamped parts to the next process, and then the box body and the bottom are stamped into a box.

7. Quality inspection process

Our company has accumulated a set of effective quality inspection management principles and systems in the long-term management practice: the implementation of self-inspection of operators, mutual inspection between workers and special inspection of full-time inspection personnel The products are inspected according to the technical standards stipulated in the drawings, process and contract, and the product is judged to be qualified. This inspection fully reflects that the factory must be responsible for the quality of the products it produces.

Then the test report is signed and signed by professionals, and the qualified products are packed and packaged, and then they can be shipped.

8. Transportation

The transportation methods are mainly divided into railway, highway, sea, and air. The transportation method is selected according to the customer's requirements for timeliness. The transportation is generally selected by road transportation, which has the advantages of price and timeliness compared to other transportation methods. Note: The transportation and logistics costs of the product are borne by the customer.

The above is the basic process of moon cake iron packaging production. Customized gift tin box please contact us

.png)

.jpg)

.jpg)

.jpg)

Latest comments