Custom color printed...

The difference between tinned iron box and galvanized iron box

1. What is tin electroplating

·Electrolytic Tinplate is a kind of high value-added cold-rolled coated steel (ETP or TP) produced by plating a very thin layer of tin (1.1~15.1g/m2) on cold-rolled sheet steel.

2, the characteristics of tinplate

·Safety: Tin is non-toxic, not absorbed by the human body, and can be used for food and beverage packaging;

·Aesthetic: The tinplate has a silver-white metallic luster and can be printed and painted;

.Corrosion resistance: tin is an inactive element, not easy to rust and corrode, and has a good protective effect on the substrate;

· Weldability: tin has good weldability;

Environmental protection: tinplate products are easy to recycle;

·Workability: Tin has good ductility, and the steel substrate provides good strength and deformation.

3, what is chrome-plated iron

·Because of the high price of tin and the scarce reserves, Japanese steel mills have developed chromium-plated steel (50~150mg/m2) on thin steel plates, called chrome-plated iron.

.Tin Free Steel (TFS)--Europe also known as Electrolytic Chromium CoatedSteel (ECCS)

4, the difference between tinned iron box and galvanized iron box

Appearance: The tin-plated iron box has a bright silver-white metallic luster, and the galvanized iron box has a darker luster;

Corrosion resistance: The tin-plated layer of tin-plated iron boxes can provide a certain degree of corrosion resistance, but the chromium-plated layer of galvanized iron boxes is extremely thin and basically does not provide corrosion resistance, so galvanized iron boxes are not suitable for long-term storage containers;

Finishing: The adhesion of the surface of the galvanized iron box to the paint is better than that of the tinned iron box

·Weldability: Galvanized iron boxes have no self-welding capability, so they cannot be used to produce three-piece cans, only top and bottom lids or two-piece cans.

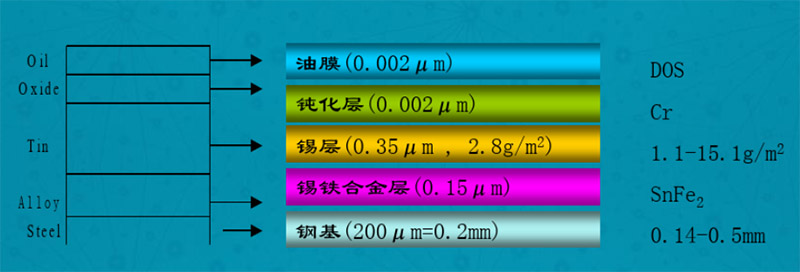

5, the coating structure of the tinplate box

.Oil--Oil film (0.002μm)--DOS oil

.Oxide --passivation layer (0.002μm) --Cr

.Tin--tin layer (0.35μm, 2.8g/m2)--1.1-15.1g/m2

.ALLoy--tin-iron alloy layer (0.15μm)--SnFe2

.Steel--Steel base (200μm=0.2mm)--0.14-0.5mm

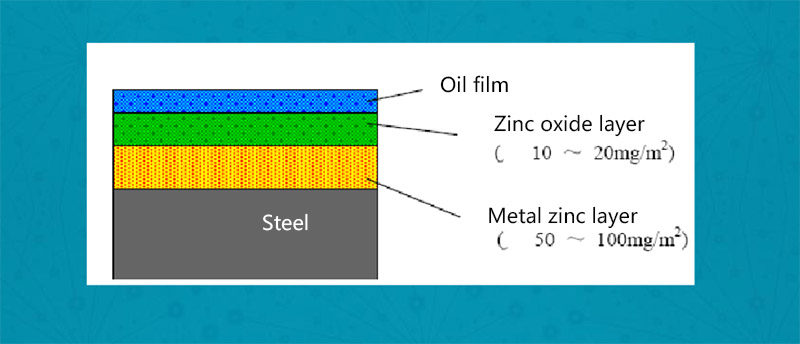

6, the galvanized layer structure of the chrome-plated iron box

.Oil film

.Chromium oxide layer (about 10~20mg/m")

.Metal chromium layer

.Steel plate (about 50~100mg/m2)

7, tin-plated iron box and galvanized iron box production process

Steelmaking—→Continuous Casting—→Hot Rolling—→Pickling—Plating—Leveling——Annealing—Cold Rolling Passivation—→Cleaning—→Greasing—→Packaging

8, tinned iron box and galvanized iron box use

Packaging applications such as can-making and lid-making are the most important applications, while a small amount is used for electronic applications.

Nine, the classification of tinned iron boxes and galvanized iron boxes

·1, classified by standard

·2, classified by rolling process

·3, classified by brand

·4, classified by substrate type

·5, classified by annealing method

·6, classified by surface morphology

·7, classified according to the amount of tin/chromium plating

·8, classified by passivation method

9. Classified by cutting board

·10, classified by volume

1. Tinned iron boxes and galvanized iron boxes are classified according to standards

·The international standards for tin plating and chrome plating include Japanese, European and American standards. Among them, the Japanese standard is the mainstream standard, which can be accepted by global customers.

·JIS3303 is the standard for tin plating and substrate, and JIS3315 is the standard for chrome plating.

·European customers often require European standards, and the current implementation is EN10202. The grade system of EN10202 is distinguished by yield, which is quite different from the Japanese standard, national standard, etc. by Rockwell hardness.

·Since the United States basically does not export tinplate, American standards are basically not applied internationally.

2. Classified by rolling process

Single Reduce: The substrate is annealed after hot rolling and cold rolling, usually with a thickness of 0.17~0.5mm, referred to as SR.

Double Reduce: The substrate is made by hot rolling, annealing, cold rolling, and then cold rolling. The second cold rolling is named after it. The thickness is usually 0.12~0.36mm, referred to as DR.

Due to the thinner thickness and higher strength of the secondary cold rolling, the cost of can making can be reduced, and the overall use ratio is continuously increasing. Because the secondary cold rolling production process is more sophisticated and complex, and the supply capacity is smaller than that of the primary cold rolling, it is a better-selling product in the overseas market.

3. Classified by substrate type

·MR: The most common steel grade, with less residual steel-making impurities, excellent mechanical properties and corrosion resistance;

·L: used to produce high corrosion resistance tin plate for food cans containing acidic content (orange, yellow peach, pineapple, etc.) and the inner surface of plain iron

Substrate steel type, this kind of tin plate is often called K plate;

·D: Highly processability tin plate base steel grade for the production of two-piece drawing cans, this kind of tin plate is often called DI material;

SPCC: Chinese characteristics, made of ordinary hot-rolled SPHC, usually used for miscellaneous cans.

4. Classified by annealing method

·Continuous Anneal, referred to as CA;

·Batch Anneal, referred to as BA

5, according to the metal iron surface morphology classification

·Bright Finish: The substrate is a smooth surface with a very fine grindstone pattern;

·Rough surface Stone Finish: The substrate is a grindstone pattern with a certain directionality:

·Silver Finish: The surface of the substrate is rough and dull;

Matte Finish: The surface of the substrate is rough and dull, and the tin-plated layer is not reflowable; the rough surface is the most common surface, followed by the bright surface. Both silver and matte surfaces have special uses and are rare.

·Rough surface can be divided into R1 and R2 according to the different roughness. Among them, R1 is also called Fine Stone, but this distinction has higher requirements for the contract organization of the steel plant.

6. Classified according to the plating volume of tin-plated iron box and galvanized iron box

The common tin plating amount is 1.1, 2.8, 5.6, 8.4, 11.2, 15.1, and internationally there are 1.4, 2.2, etc. The unit is g/m2 on one side, and the two sides can be combined separately.

·If the amount of tin plating on both sides is different, it is called differential thickness tin plating. The steel mill can print a marking line on one side to facilitate the user to distinguish. Marking lines can be divided into parallel marking lines and edge marking lines. Generally, the edge marking lines are more popular with customers.

·The common chromium plating amount is 50~150, the unit is mg/m2 on one side, and the same amount on both sides.

7. Tinned iron boxes and galvanized iron boxes are classified by passivation method

There are four ways of tinning passivation: chemical passivation, electrochemical passivation, low chromium passivation and no treatment. Among them, electrochemical passivation is the default method; the general code of electrochemical passivation is 311; low chromium passivation is only used for the production of plain mushroom pots; no treatment (passivation with water) is only used for the production of DI materials.

8. Tinned iron boxes and galvanized iron boxes are classified according to the cutting method

Straight cut: cut into squares, which is the default cutting method;

· Scroll cut: cut into a wave-like shape, also called lace board, mainly to improve the utilization rate of the material for the cover. Customers need to prepare their own tools;

·Cutting board English is usually Cut or Shear, cutter is Die, and slitting is Slit.

9. The materials of tin-plated iron boxes and galvanized iron boxes are classified by volume

Eye to sky coils: Eye to sky coils: the coil core is up and there is a wooden bracket underneath, which is the default export coil packaging method; horizontal coils Eye to side coils: the coil core is horizontal, some have tic-tac-toe, some are not, overseas Basically not accepted by customers;

Coil ID: Generally, there are 420mm and 508mm.

10, order tin-plated iron box and galvanized iron box elements

·The ordering elements of tin-plated iron boxes generally include: food-grade international standards, box structure, printing process, size (the default order is length * width * height), tin plate thickness, smooth surface plating (silver light iron box, Frosted iron), order quantity, etc.;

To order tin-plated tin boxes, you must confirm the contents with the customer. Special contents such as milk powder, high-protein foods, mushrooms, fruits, etc. have special requirements for tin box production.

Conclusion: Our factory was established in 2005. It covers an area of 10,000 square meters and has more than 300 employees. It is a professional manufacturer of metal tin box packaging. Products include: 1. Card packaging, bluetooth headset packaging box, mobile phone, U disk tin box, CD/DVD tin box.2. Food packaging: biscuits, biscuits, candy, chocolate, coffee, health products3. Gift packaging: tea, wine, cigarettes4. Other uses: coins, pens/pencils, watches, cosmetics, tin plates, tin buckets, tin badges. We have more than 30 technical staff and mold development technicians, and more than 300 sets of equipment, which can ensure that we provide high-quality products. As a professional tin box manufacturer, we can design any size and shape according to customer requirements. We have our own professional quality control team to implement our production policy to ensure our high quality and on-time delivery. "High quality, competitive price and considerate service" is our aim. We sincerely hope to establish long-term business relationships with global customers on the basis of equality and mutual benefit. If you have any suggestions or you can leave us a message, we will answer your questions by email.

Latest comments