As a professional...

What are the commonly used packaging materials

single powder paper

1. Commonly used carton materials, the thickness of paper ranges from 80g to 400g, and for higher thicknesses, two pairs are required.

2. The paper is glossy on one side and matte on the other side, only the glossy side can be printed

3. Printing of various colors can be realized, and there is no limit to the color

4. The commonly used surface treatment processes after printing are: 1. Over glue 2. Over UV 3. Quality printing 4. Convex

double flour paper

1. Commonly used carton materials, the thickness of paper ranges from 80g to 400g, and for higher thicknesses, two pairs are required.

2. Double-sided gloss for double-sided printing

3. The biggest difference from single powder is that it can be printed on both sides

4. The commonly used surface treatment processes after printing are: 1. Over glue 2. Over UV 3. Hot stamping 4. Embossing

pit paper

1. Compared with ordinary paper, it is more straight and has stronger bearing capacity

2. Commonly used are single pit, double pit, and three pits

3. Various colors can be printed, but the effect is not as good as single powder

4. The commonly used surface treatment processes after printing are: 1. Over glue 2. Over UV 3. Hot stamping 4. Embossing

Specialty paper

1. There are many kinds of special paper, here we only mention the ones used in our packaging materials: embossed paper, patterned paper, "Ningcai" pearl pattern paper, "Xingcai" metal pattern paper, gold paper, etc.;

2 These papers have been specially treated, which can improve the quality of the packaging, embossing and embossing can not be printed, only surface hot stamping, star mining, gold paper, etc. can be printed in 4 colors

Gold and silver cardboard

1. Use UV transfer technology to apply a layer of UV oil on the surface of the paper through a blanket, and then transfer the light column film or special pattern to the printed paper through a roller. Make the surface of the paper produce a beam of light to have the effect of laser paper:

2. It can only be printed by UV machine, and various pattern effects can be achieved. It is more textured than ordinary paper and has different kinds of luster. But the cost is much higher

Composite bag material

1 The compound bag is suitable for vacuum packaging or general packaging of food, electronic products, chemicals, medicine, tea and other products

2. The process that can be done is basically the same as that of paper, which can be screen printing, printing, hot stamping

Blister material

1. Blister is a transparent material, the main raw material is PVC, PE or PET

2. It can be directly replaced by paper to make a box, and can also be formed with paper cards

3. It is used to fix the product inside the package, which is called a blister

4. Can be screen printed, printed, or hot stamped

5. It can be printed on the machine, but the printing cost is high. Generally, only silk screen printing is used for small production.

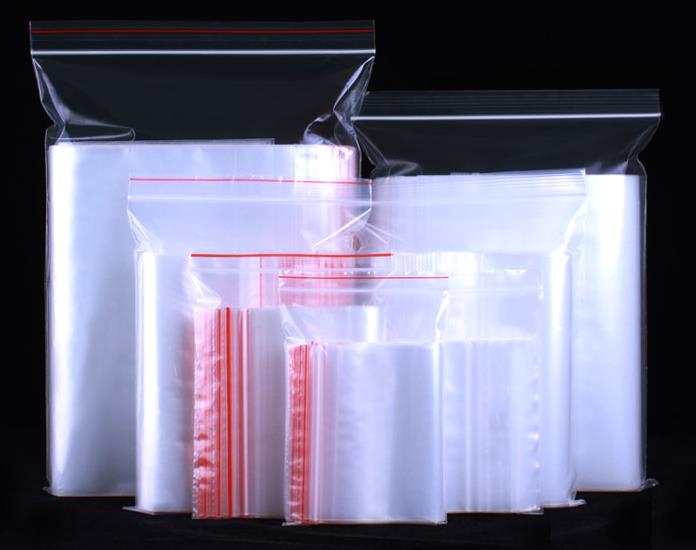

OPP bag

1. The OPP bag is a stretchable polypropylene, a kind of plastic, which is actually a plastic bag

2. Before packing the outer box, put an OPP bag on the product, which looks clean and hygienic

3. There are pp plastic bags and pe plastic bags of different materials

4 has the characteristics of high transparency and brittleness. Various patterns and punching can also be printed according to customer needs

EVA material

1. The chemical name is ethylene-vinyl acetate copolymer, and the finished product made of it has good flexibility, shock resistance, anti-skid, and strong pressure resistance.

2. Use inside the box to fix and protect the product

3. There are a variety of colors to choose from, and the surface can be flocked or wrapped in flannel to enhance the visual effect

sponge material

1. It is a porous material with good elasticity. The density of the holes is different, and the elasticity is different

2. Use inside the box to fix and protect the product

3. There are a variety of colors to choose from, generally used directly, not in the superposition process

heat shrink bag

1. It is a transparent bag made of a material with strong shrinkage at a certain temperature, which is used to protect the packaging

2. It is only used to protect the packaging, no other processes

Tin-plated iron material

1. Tin-plated iron, the main materials are steel and tin, there is a layer of tin on the iron sheet

2. Tin-plated iron has strong corrosion resistance, and its own strength is hard, and it has good ductility

3. Tin-plated iron combines the strength of steel with the corrosion resistance and aesthetics of tin, so that tinplate has the characteristics of non-toxicity, high strength, corrosion resistance and good elongation, making it industrially Use ten

Divided widely.

4. Tin-plated iron is widely used in production and application. It is generally used for grease cans and chemical cans used in food or beverage processing. Because tinplate has strong corrosion resistance, it can protect the safety of food to the greatest extent. ,

And make it more convenient for modern people to eat.

.png)

.jpg)

.jpg)

.jpg)

Latest comments