As a professional...

Design parameters of iron tank structure

(1) Tank shape and specifications

The most commonly used three-piece cans are round cans (vertical round cans, flat round cans), in addition to square cans, oval cans, trapezoidal cans and other special-shaped cans. In the selection of the tank shape, factors such as packaging requirements and cost should be considered comprehensively. The round tank is the easiest to manufacture, the most economical in materials, and the largest in all tank-shaped containers, but the shape is not distinctive. The special-shaped can has a unique shape, but it is difficult to manufacture, and the materials and costs are relatively high. Considering from the most economical principle, round tanks should be used as much as possible in the design, and special-shaped tanks should be selected only when there are special requirements.

The size of the tank, that is, the size of the tank container. The general three-piece can can be determined according to the standard specification series. For tank containers with special requirements or special shapes, the specifications can be determined according to actual needs. The process of determining the size of the three-piece can is:

① Determine the shape of the tank according to the packaging requirements of the packaged object;

②Calculate the required capacity based on the packaging volume of the packaged material, and calculate the tank volume with the filling rate of the packaged material (about 85% to 95%);

③Finally, choose the size of the tank according to the calculation result.

(2) Can body

①The can body seam can be cured by the aforementioned three-piece can processing method. The can body seam formed by different processing methods is different. There are four types of seam structure.

②Cut-off angle and cut-off cut-off angle is the upper and lower corners cut off from one end of the can body plate, and the two acute angles cut from the other end are the cut-offs. The purpose is to reduce the overlap of the steel plate after the two ends of the can body are hooked , Easy to flanging and sealing. The depth of the chamfer and notch is 2. 1 ~ 2. 5mm, increasing with the increase of tank diameter, allowable deviation is ± 0. 15mm.

③End folding (hooking) The purpose of the end folding is to make the two ends of the can hook together. Hooking requires that the two ends of the can body be hooked 35 ° to 45 ° opposite to the can body, and the width of the salty hooks at both ends is the same, and the width of the hook is 2. 3-2. 8mm, increasing with the increase of tank diameter, allowable deviation is ± 0. 15mm

④Seam structure After the two ends of the can body plate are hooked and hooked to each other, the hook is flattened by mechanical pressure through a stepper to form a seam structure of the can body.

After flattening, the seam size standard is:

seam width b 2.9—3.4mm (increased with the increase of tank diameter)

seam thickness t 4tb+e(mm); among them, tb is the thickness of the can body plate; e is the correction coefficient, generally ≤ 0. 2mm.

The depth of the overlap gap h 0.5 ± 0.1mm.

Seam structure size standard is:

seam width b 0.6—1.0mm (increased with the increase of tank diameter); seam thickness h ≤ 1. 4tb, where tb is the thickness of the can body plate (mm).

⑤ Can body rigid ring When the diameter of the can body is large, in order to increase the rigidity, the rigid ring can be rolled in the circumferential direction. At the same time, the pre-compression ribs are pre-pressed at the longitudinal joints so as to roll the rigid ring.

⑥ Flanging The part turned out from the lower edge of the can body is the flanging, and its purpose is to seal with the can lid or bottom.

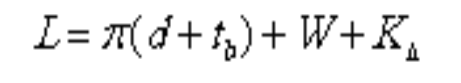

⑦The calculation of the size of the can body slab Taking a round can as an example, the calculation formula of the can body slab size is:

( 1 )

( 1 )

where d-- tank inner diameter (unit: mm)

L-- length of can body plate (unit mm)

tb- Thickness of can body plate (unit: mm)

Ka-- correction factor (unit mm)

W—— the total width of the can body flange (unit mm)

( 2 )

where H--- the width of the can slab (unit: mm);

h-- the outer height of the tank (in mm).

The length and dimension deviation of the can body slab is ± 0. 25mm; the deviation of the width dimension of the can body blank is ± 0. 1mm, the cutting deviation should not exceed 0. 25%.

For resistance welded tanks, the length of the blank plate is calculated according to formula (3.1) when W = 0, and Ka generally takes 0. 6--1. 6mm.

``` For large round tanks, when designing a rigid ring, the width of the slab calculated according to formula (3.2) should be appropriately enlarged.

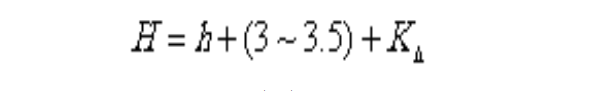

⑧The thickness of the can blank plate The thickness of the plate used in the general metal can container is 0. 15 ~ o. Between 50mm, the selection principle is that the larger the diameter of the can body is larger, and the smaller the diameter of the can body is smaller. For food cans and other pressure vessels, it should be determined according to the pressure in the can and the allowable stress of the material. The calculation formula for the thickness of the can body plate is:

(3)

where p-- pressure in the tank (unit MPa);

d-- the inner diameter of the tank, (unit cm)

[]—— allowable stress of can material (in Pa);

tb- the thickness of the can body plate, (unit cm).

(3) Tank lid and tank bottom

①Expansion ring pattern The structure of the expansion ring pattern of the tank lid or bottom is shown in Figure 3. 27. Its structure is generally composed of one or two external ribs and several levels of 30 ring slopes. The shape of the ring depends on the diameter of the tank lid or tank bottom. 7 Select. The expansion ring pattern of the can lid and the can bottom can increase the mechanical strength of the can lid (bottom); the expansion ring can avoid the damage of the can curling caused by the change of the ambient temperature and ensure the tightness.

②Flanging The edge hook formed by bending the outer edge of the lid (bottom) inward will be crimped and sealed with the flanging of the can body. Figure 3, 28 and Table 3 for the general shape and size of the outer edge of the can lid (bottom). 8. Figure 3 shows the shape and main dimensions of the flange of the three-piece easy-opening can. 29 and Table 3. 9 .

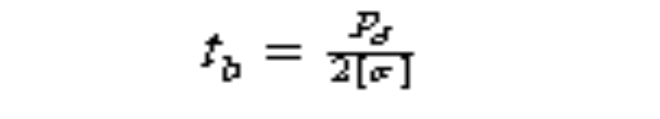

③Calculating the size of the can cover (bottom) blank plate The calculation formula for the size of the round can cover (bottom) blank plate is:

where D1——The calculated diameter of the can cover (bottom) blank, mm;

D—— tank inner diameter, mm; KD~—— correction factor.

K. The selection of I value is related to tank inner diameter size, equipment conditions, steel plate and film thickness. For details, please refer to Table 3. 10 Select.

(4) Double curling

Double crimping is a sealing form formed by the three-piece can body and the can lid (bottom) being rolled together, and it is also the only sealing form at present. Its structure is composed of two-layer can body material, two-layer can cover (bottom) material and sealant embedded between them. Its structure is shown in Figure 3. 30.

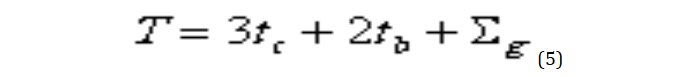

①Crimping thickness (T) Crimping thickness then refers to the maximum dimension perpendicular to the crimp stack measured on the outside of the crimp. The calculation formula is as follows:

where tc—— the thickness of the can lid (bottom) blank, mm;

tb—— the thickness of the can slab, mm;

∑ g—— the sum of the gaps between layers, about 0.15 ~ 0.25mm.

Crimping thickness f is affected by the crimping wheel sealing pressure. Generally, the r value is small when the pressure is large, and the value is large when the pressure is small.

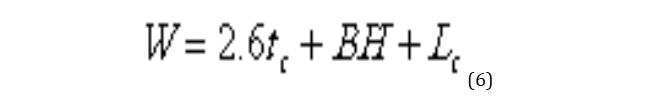

②Hemming width (w) Hemming width refers to the maximum dimension of the layer parallel to the hemming measured from the outside of the hemming. The calculation formula is as follows:

where BH—— length of body hook, mm;

Lo—— body hook gap, mm, the smaller the better.

The width of the curling edge is also affected by the shape of the pressure roller groove, the sealing pressure and the thrust of the lower tray. In addition, the body hook length BH has a greater impact on the tank. Generally speaking, a small BH value is prone to leakage. If the BH value is too large, it is prone to vertical edges, so the body hook length BH must be moderate.

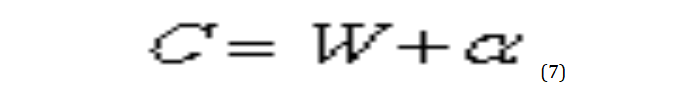

③ Countersunk degree (C) Countersunk degree refers to the distance from the crimp top to the cover plane. It is generally determined by the thickness of the upper indenter flange, namely:

In the formula, W---- width of curling edge, mm;

a—correction coefficient, generally 0. 15-0. 30mm.

④Can body hook length (BH) The can body hook length refers to the length of the can body bent inward into a hook shape. Its value is 1. 8--2. 2mm.

⑤The length of the can lid hook (CH) The length of the can lid hook refers to the length of the round edge of the can lid turned to the inner curved part of the crimp. The length of the cover hook depends on the shape of the groove of the head roller, and its value is basically the same as the body hook.

⑥ Overlapping length (OL) Overlapping length refers to the overlapping length of the inner cover hook and body hook of the crimp after the double crimp is formed. The calculation formula is as follows:![]()

where BH---- size of body hook, mm;

CHl---- size of cover hook, mm;

c. ——The thickness of the can cover (bottom) blank, mm;

W---- Width of curling edge, mm.

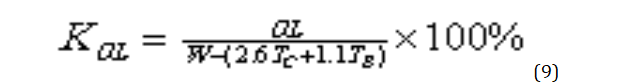

⑦ Overlap rate (KOL) Overlap rate refers to the degree of overlap between the inner cover hook and the body hook of the crimping. The calculation formula is as follows:

where KOL---- overlap rate, %;

OL—— overlapping length, mm;

W—— hemming width, mm;

Tc——The thickness of the can cover (bottom) blank, mm.

For round cans, KOL) 50% is required.

.png)

.jpg)

.jpg)

.jpg)

Derniers commentaires