As a professional...

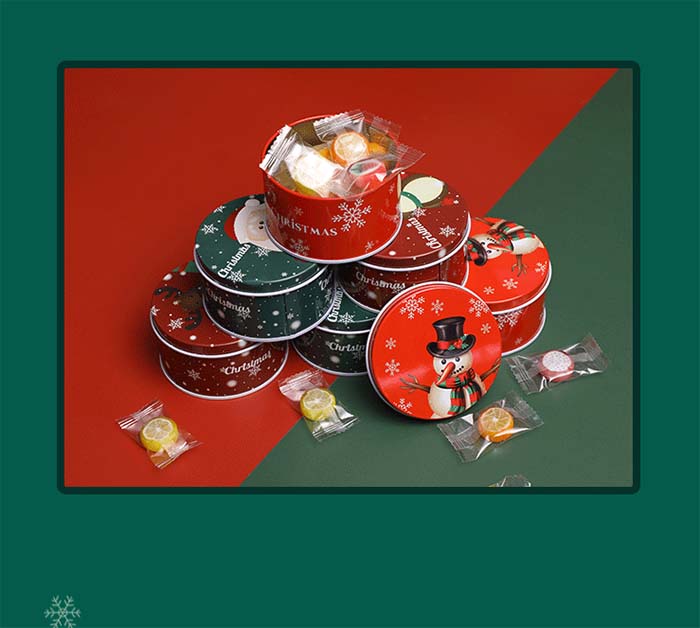

How is the exquisite tin box packaging of Christmas gift biscuits made?

With the progress and development of tinplate packaging box production technology, the packaging and printing process of Christmas biscuit tin box is constantly updated, and the printing process of Christmas biscuit packaging box has been simplified. The production process of Christmas gift biscuit tin box packaging is different from traditional paper gift packaging boxes. The production of high-end Christmas gift biscuit tin box packaging is a series of delicate and complicated processes. Generally, high-end Christmas gift boxes are small and exquisite in appearance. Each gift box is beautifully decorated and has a unique box shape. The packaging box of the decorative mirror represents the festive atmosphere and service, and brings you a happy mood. Where can I customize a beautiful gift biscuit tin box packaging? This article will answer your question.

1. Packaging design of Christmas gift biscuit tin box

Many gift biscuit tin box packaging designs are designed by enterprises or customers themselves or by a professional design company, because design is the first step in making gift biscuit tin box packaging. What kind of pattern needs to be printed, what size and box shape should be customized The structure and so on. It is true that we have a professional biscuit packaging box design team to provide customers with free design services.

2. Christmas gift biscuit tin box packaging proofing

The first customized printed gift biscuit tin box packaging usually requires proofing, and it is made strictly in accordance with the design drawings. The samples must be pressed with a stamping machine, because the color of the digital sample may be different when the sample is printed again in large quantities. , And the solid samples can ensure that the color and box type in mass production are consistent with the design drawings.

3. Christmas gift biscuit tin box packaging layout

After the proof of the gift biscuit tin box packaging is confirmed, it can be mass-produced normally. For the production and production of packaging and printing plants, this is actually the first step to achieve; the color craftsmanship of gift packaging boxes is very beautiful, so the layout and printing colors are also varied. Many gift biscuit tin boxes not only have 4 basic colors, but also special colors, such as special red, special blue, black, etc. These are all special colors, which are different from the normal four colors. A few colors are just a few PS versions, and the spot colors are unique.

4. gift biscuit tin box packaging materials

The material selection of the holiday gift biscuit tin box packaging has been determined during proofing. It is made of food tinplate with a thickness of 0.23-0.35mm. Here is the type of tinplate used for proofing the gift biscuit tin box packaging. . Classification of tinplate: tin iron and silver light iron are commonly used.

1). Tin iron: It is the common name of electroplated tin thin steel plate, the English abbreviation is SPTE, also known as tin plate. Tin mainly plays a role in preventing corrosion and rust. It has the characteristics of corrosion resistance, non-toxicity, high strength and good ductility. The surface plating layer has specific iron patterns and brightness, and the surface patterns are irregular horizontal stripes. The tin iron is distinguished by different tin plating amounts, usually between 1.0 and 5.6, expressed as 10#, 25#, 50#, etc.

2). Silver light iron: commonly known as frosted iron. Divided into coarse sand, fine sand, and medium sand iron, it is not easy to scratch during use, but its surface anti-rust ability is poor. Fine sand iron is commonly used.

The three commonly used are: galvanized iron (the galvanized layer with ice and snowflakes on the surface is called ice iron, and the surface has dark flowers, usually used to make buckets), chrome-plated iron (with tinned bright and iron patterns, and the surface is silver gray ), base 3. Plate iron (no tin plating on the surface, generally used for double-sided printing).

5. Christmas gift biscuit tin box packaging and printing

The printing process of gift biscuit tin box packaging is very demanding. The most taboo is the color difference, ink dots, inaccurate needle registration, scratches and other problems, which will also bring troubles to post-press processing. The ink used on the inside and outside of the gift biscuit tin box is a kind of ink containing special substances, which is used to prevent the contents of the gift biscuit box from corroding the tin box, preventing food from being contaminated on the wall, and can better extend the storage of food time.

At the curling edge of the gift biscuit tin box packaging, we can clearly see that the application of this layer of ink containing special substances is not only to prevent corrosion, but also to protect the gift biscuit tin box packaging from being scratched and rusted by external forces. And this layer of paint can also add beauty to the iron box.

Note: Printing ink is a kind of non-toxic, harmless, odorless, good adhesion, good adsorption, good flexibility and good corrosion resistance, and has outstanding high temperature resistance, and it will not be harmful under high temperature heating. Material, will not lose the original luster and other functions.

I have heated a canned beef in a microwave oven. After heating, the inner coating of the tin box has not changed at all! Therefore, as some people say, the inner coating in the iron box is not resistant to high temperatures. Of course, it is not recommended to do this. To heat things, use special utensils. So what exactly is this coating inside? Such coatings are phenolic resin coatings, epoxy-phenolic resin coatings, acrylic resin coatings and aluminum powder coatings. So you can buy with confidence!

6. gift biscuit tin box packaging and printing process

Gift biscuit tin box packaging, top paint, color box packaging boxes are commonly used over gloss glue, over matte glue, uv, over varnish, over matte oil, bronzing, etc.

7. Christmas gift biscuit tin box packaging is stamped and formed.

The stamping process is to make a layer of tin box packaging and beautify the structure of the biscuit tin box. Since the gift biscuit tin box is made of tinplate, its excellent ductility and ease of manufacturing are the biggest advantages of tin box production. Iron box manufacturers can make various forms of iron boxes and cans with the help of molds. And the surface of the biscuit tin box can also be processed by protruding or embossing, so that the pattern, text, and logo have a three-dimensional vision and increase the design effect of the tin box. The stamping process of gift biscuit tin box packaging is a more important part of the production process, and it is also the last process. If it is not done well, the previous efforts will be wasted. When stamping, pay attention to the indentation and do not burst the line or die-cutting.

8. Christmas gift biscuits tin box packaging inspection

The gift biscuit tin box needs to be tested after the production process is completed. After the test is qualified, it can be packaged and shipped.

Founded in 2006, our factory has 10,000 square meters of workshops and more than 2,000 sets of molds. It is an enterprise specializing in the creative design and tinplate packaging of Christmas gift biscuit tin boxes. We have rich experience in biscuit tin box manufacturing. In March-September, we have produced more than 350,000 Christmas gift biscuit tin boxes for "Sodexo", "ADM" and "Stella Artois", and provide our partners with free packaging design and sales services with high-quality services to create great Market-competitive packaging solutions.

If you have suggestions or comments, you can give us attention, we will answer your questions in the form of email, welcome to consult and order

.png)

.jpg)

.jpg)

.jpg)

Derniers commentaires